NEMA 4 NHP Cabinet Cooler® Systems w Therm

Applications

- Programmable controllers

- Line control cabinets

- Motor control centers

- Relay panels

- NC/CNC systems

- Modular control centers

- CCTV cameras

- Computer cabinets

- Cool laser housings

- Electronic scales

NEMA 4 Cabinet Cooler Advantages

- Low cost

- Compact

- Cooling capacities up to 5,600 Btu/hr. (1,641 Watts)

- Quiet

- Install in minutes

- Maintain NEMA 4 integrity (IP66)

- Stabilize enclosure temperature and humidity

- No CFC's

- No moving parts - maintenance free

- Mount in standard electrical knockout

- Stop nuisance tripping

- Stop heat damage

- Eliminate fans and filters

- Eliminate lost production

- Stop circuit drift

- Stop dirt contamination

- Provide washdown protection

NEMA 4 (IP66) Non Hazardous Purge Cabinet Cooler Systems, Thermostat Control (120V) |

|

| Model | Btu/hr. (Watts) |

| NHP4804 | 275 (80) |

| NHP4808 | 550 (162) |

| NHP4815 | 1,000 (293) |

| NHP4825 | 1,700 (498) |

| NHP4830 | 2,000 (586) |

| NHP4840 | 2,800 (821) |

| NHP4850 | 3,400 (997) |

| NHP4860 | 4,000 (1,171) |

| NHP4870 | 4,800 (1,406) |

| NHP4880 | 5,600 (1,641) |

NEMA 4 (IP66) Non Hazardous Purge Cabinet Cooler Systems, Thermostat Control (240V) |

|

| Model | Btu/hr. (Watts) |

| NHP4804-240 | 275 (80) |

| NHP4808-240 | 550 (162) |

| NHP4815-240 | 1,000 (293) |

| NHP4825-240 | 1,700 (498) |

| NHP4830-240 | 2,000 (586) |

| NHP4840-240 | 2,800 (821) |

| NHP4850-240 | 3,400 (997) |

| NHP4860-240 | 4,000 (1,171) |

| NHP4870-240 | 4,800 (1,406) |

| NHP4880-240 | 5,600 (1,641) |

Side Mount Kits

EXAIR's Side Mount Kits make mounting on the side of an electrical enclosure possible when there is limited space on the top or side. (NEMA 4 and 4X Cabinet Cooler Systems must be mounted vertically.) Side Mount Kits maintain the NEMA rating of large and small NEMA Type 12, 4, and 4X enclosures. they mount in a standard electrical knockout (1-1/2 NPS). Side Mount Kits for NEMA 12 Cabinet Cooler Systems have an aluminum construction. Those for NEMA 4 and 4X Cabinet Cooler Systems are Type 303 or Type 316 stainless steel.

What is an EXAIR Cabinet Cooler System?

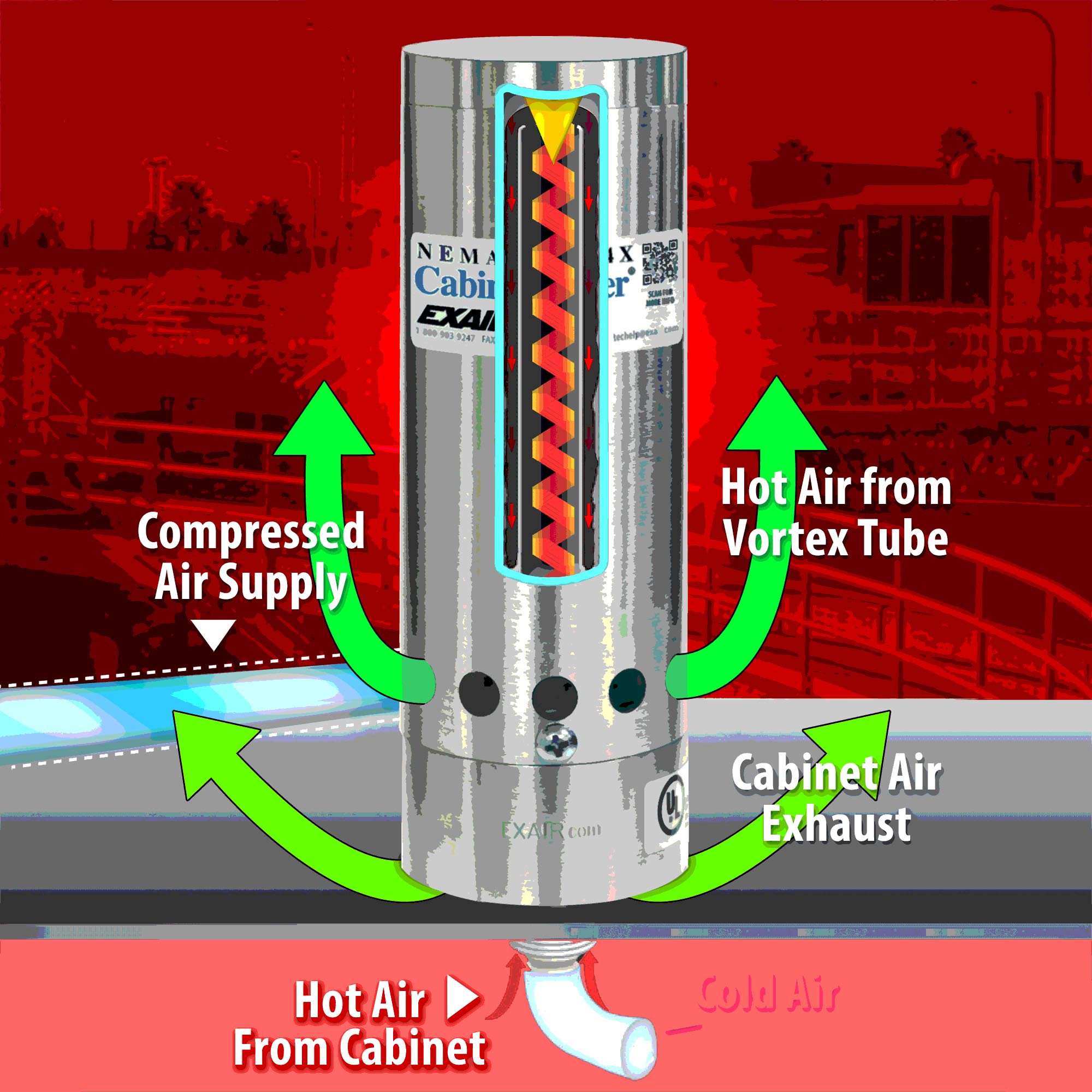

EXAIR Cabinet Coolers are a low cost, reliable way to cool and purge electronic control panels. They provide air conditioning for the electrical enclosures, eliminating electronic control downtime due to heat, dirt and moisture! These panel cooling systems for enclosures incorporate a vortex tube to produce cold air from compressed air - with no moving parts.

The compact Cabinet Cooler is an easy to use air conditioner that can be installed in minutes through a standard electrical knockout. NEMA 12, 4 and 4X Cabinet Coolers that match the NEMA rating of the enclosure are available in many cooling capacities for large and small control panels.

Why EXAIR Cabinet Coolers?

When the electronics inside a control cabinet overheat, the machine can shut down due to tripped overloads and breakers or heat damage to the circuit boards. Unreliable cooling methods such as fans, heat exchangers, refrigerant air conditioners, and heat pipes are prone to failure as a result of mechanical wear, and clogged filters.

EXAIR Cabinet Coolers provide cold air for large and small control panels and are maintenance free. They have no moving parts to wear out. All Cabinet Coolers are UL, ULC Listed and/or CE compliant and have a five year “Built To Last” warranty.

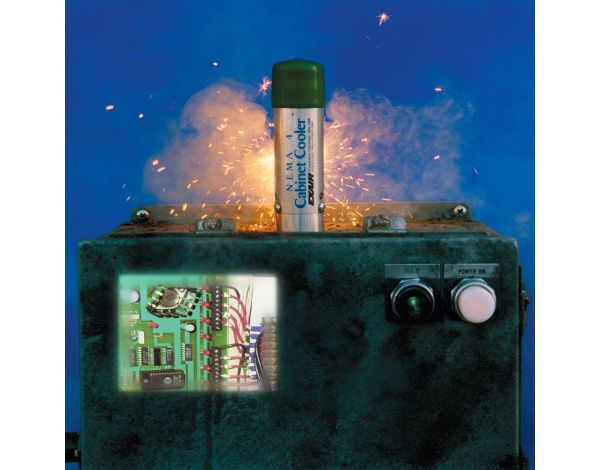

Heat Can Stop Your Machines

It happens when you least expect it. High temperatures can cook the electronics that control your machines, resulting in erroneous readings, trip-outs or fried circuit boards. Cooling the electrical cabinet can eliminate these problems, but how will you do it?

Fans

Opening the panel door and aiming a fan at the circuit boards is a bad idea.

- It is an OSHA violation that presents a shock hazard to personnel

- The fan blows hot, humid, dirty air at the electronics

- The cooling effect is minimal

- It is likely to fail again since the environment is still hot

Heat Exchangers and Heat Pipes

These have serious limitations. On hot summer days when the temperatures of the room and inside the enclosure are about equal, there’s not enough difference for effective heat exchange.

- They fail when dust and dirt clog the filter

- The cooling capacity is limited due to ambient conditions

Refrigerant Panel Air Conditioners

These coolers are prone to failure in dirty, industrial environments when dust and dirt clogs the filter.

- It takes almost a day to install

- Vibration from machinery causes refrigerant leaks and component failures

- Compressor life expectancy is typically 2.5 years of continuous operation

- It requires a floor drain for the condensation

- Thermostat control can decrease compressor life

- Average cost for replacing a bad compressor is $750

EXAIR Cabinet Cooler Systems

EXAIR has a complete line of Cabinet Cooler Systems to dependably cool and purge your electrical enclosures. They convert an ordinary supply of compressed air into clean, cold 16ºF (-9°C) air. They mount in minutes through an ordinary electrical knockout and have no moving parts to wear out. Compressed air filtration is provided that keeps water, oil and other contaminants out of the enclosure.

- There is no room air filter to clog

- An accurate electrical thermostat control minimizes compressed air use

- All Cabinet Coolers are UL Listed to US and Canadian safety standards

- They are the only compressed air powered coolers that are CE compliant

NEMA 4 Cabinet Coolers

NEMA 4 (IP66) Cabinet Cooler systems are made from 303 stainless steel, dust and oil tight, splash resistant, indoor/outdoor capable and corrosion resistant. By incorporating a low pressure valve for all air exhaust, the valve closes and seals when not operating to maintain NEMA 4X enclosure integrity.

Thermostat control systems (Models 4804-4880) are the most efficient system because it will turn itself on and off as needed to cool your enclosure. Includes cooler, solenoid valve and thermostat, filter separator and cold air distribution kit. Models are available in 110VAC, 240VAC and 24VDC.

Continuous operation systems (Models 4704-4780) include the cooler, a filter separator and cold air distribution kit.

ETC Thermostat control systems provide on the fly temperature adjustment and an internal temperature feedback display.

High Temperature Cabinet Cooler systems should be used when ambient temperatures reach 125°F to 200°F (52°C to 93°C).

Non-Hazardous Purge (NHP) models provide a continuous positive purge within the enclosure to prevent contaminants from entering. They are suited for extremely dirty and dusty environments.

Dual Cabinet Cooler systems (Models (##50-##80) provide for additional cooling.

NEMA 4 (IP66) Non Hazardous Purge Cabinet Cooler with Thermostat - Performance |

||||

| Model | Capacity | Sound Level dBA | ||

| Btu/hr. | Watts | |||

| NHP4804, NHP4804-240 | 275 | 80 | 59* | |

| NHP4808, NHP4808-240 | 550 | 162 | 67* | |

| NHP4815, NHP4815-240 | 1,000 | 293 | 73 | |

| NHP4825, NHP4825-240 | 1,700 | 498 | 80 | |

| NHP4830, NHP4830-240 | 2,000 | 586 | 80 | |

| NHP4840, NHP4840-240 | 2,800 | 821 | 82 | |

| NHP4850, NHP4850-240 | 3,400 | 997 | 84 | |

| NHP4860, NHP4860-240 | 4,000 | 1,171 | 84 | |

| NHP4870, NHP4870-240 | 4,800 | 1,406 | 84 | |

| NHP4880, NHP4880-240 | 5,600 | 1,641 | 85 | |

| *With optional cold muffler installed. Cooling Capacity at 100 PSIG (6.9 BAR) Supply Pressure. | ||||

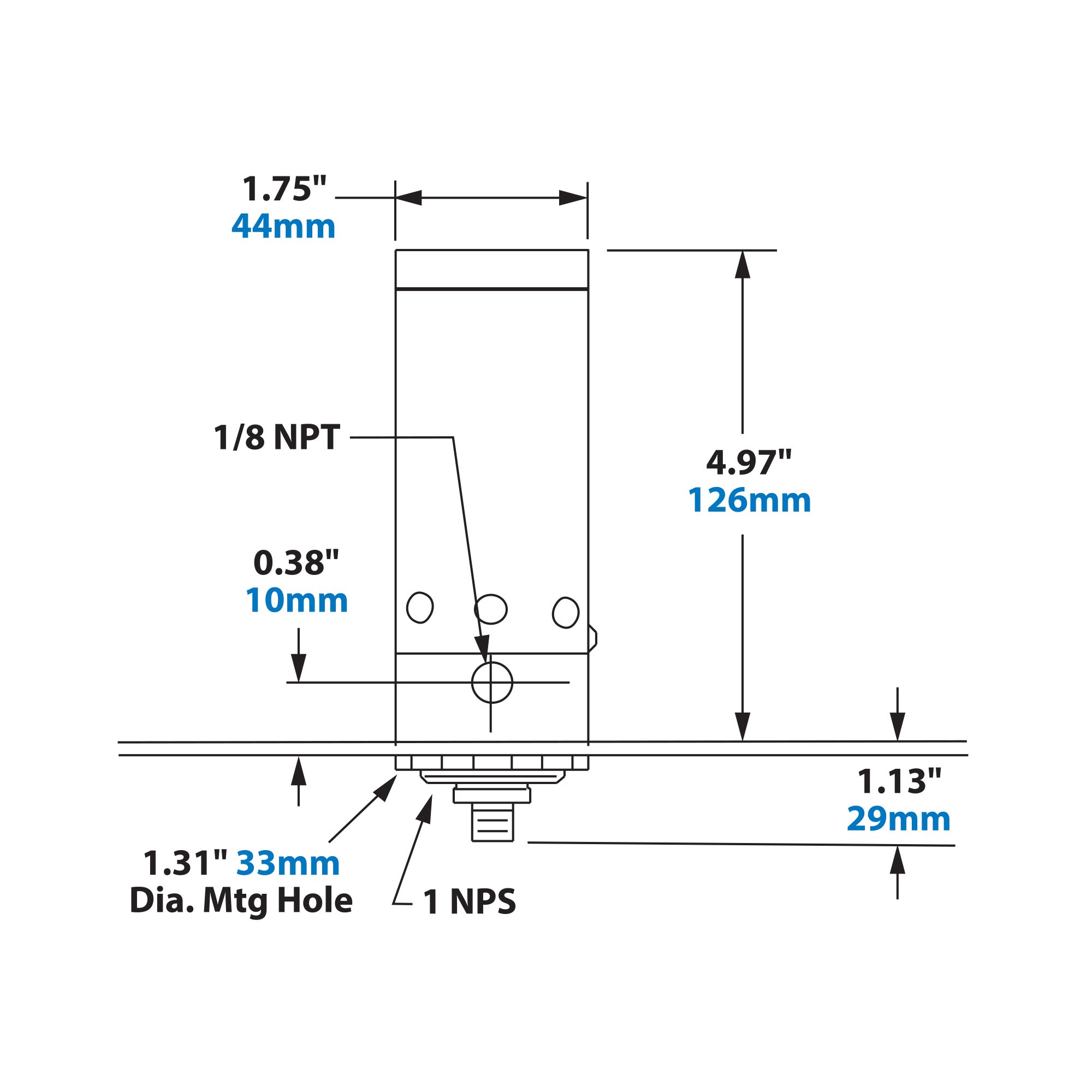

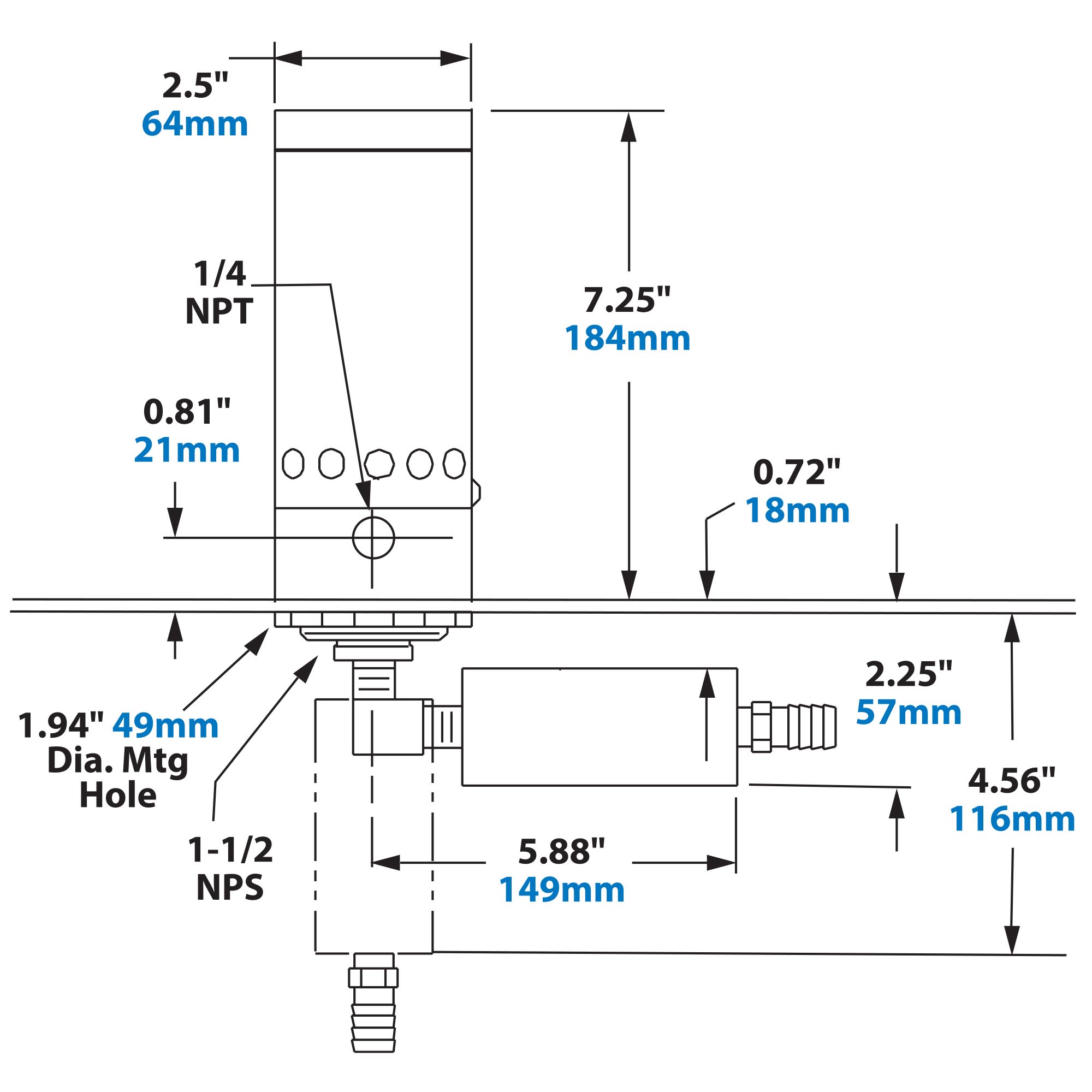

Dimensions - NEMA 4 Non Hazardous Purge Cabinet Coolers with Thermostat |

ModelsNHP4804, NHP4804-240  ModelsNHP4815, NHP4825, NHP4830, NHP4840 |

How Cabinet Coolers Work |

|

|

|

Compressed air enters the vortex tube powered Cabinet Cooler and is converted into two streams, one hot and one cold. Hot air from the vortex tube is muffled and exhausted through the vortex tube exhaust. The cold air is discharged into the control cabinet through the cold air distribution kit. The displaced hot air in the cabinet rises and exhausts to atmosphere through the cabinet air exhaust at a slight positive pressure. Thus, the control cabinet is both cooled and purged with cool, clean air. Outside air is never allowed to enter the control panel. |

|

Other Considerations

Filtration:

EXAlR Cabinet Cooler Systems include a 5 micron automatic drain water and dirt filter. This filter is critical for protection of electronics from water and dirt in the compressed air line. If oil is present in the compressed air supply, the addition of a coalescing (oil removal) filter, such as EXAlR Model 9005, is recommended.

Cold Air Distribution Kit:

The kit includes a length of flexible vinyl tubing used to direct the cold air for circulation, or to hot spots. Tubing connectors and adhesive backed clips to hold the tubing in place are provided.

Humidity:

For a continuous operating Cabinet Cooler, relative humidity inside the enclosure stabilizes at 45%. No moisture condenses inside the enclosure. (The enclosure must be sealed to prevent condensation.)

Inlet Air Temperature:

Cabinet Cooler Systems provide a 54°F (30°C) temperature drop from supply air temperature when the inlet pressure is 100 PSIG (6.9 BAR). Elevated inlet temperature will produce a corresponding rise in cold air temperature and reduction in cooling capacity. Low air pressures will also reduce the cooling capacity.

Mounting:

The Cabinet Cooler mounts to the enclosure through a drilled hole or electrical knockout. The NEMA 12 (IP54) Cabinet Coolers may be mounted on the top or side of the panel. NEMA 12 Side Mount Kits are available - Model 4909 - Small; Model 4910 - Large. NEMA 4 and 4X (IP66) Cabinet Coolers may be mounted on the top of the panel or on the side of the panel if a Side Mount Kit is used - Model 4906 - Small; Model 4907 - Large.

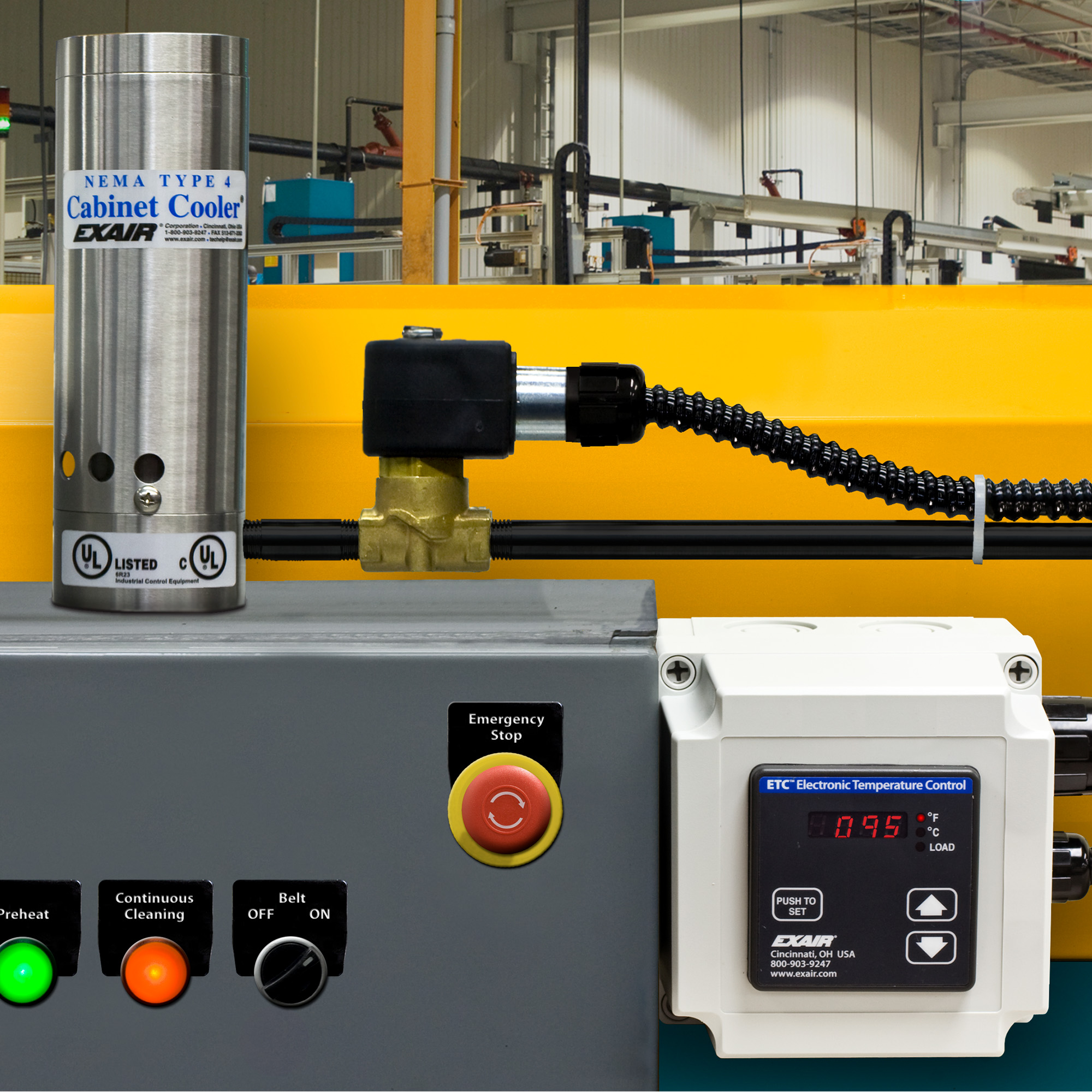

Solenoid Valve and Thermostat:

Cabinet Cooler Systems with thermostat control include a solenoid valve and thermostat that limit the flow of compressed air to only when cooling is needed. The thermostat is factory set at 95°F (35°C). It will normally hold ±2°F (1°C) inside the cabinet. Solenoid valves are available in 120V, 60Hz; 110V, 50Hz; 240V, 50/60Hz and 24VDC. All solenoids are CSA Certified and UL Listed or Recognized.

Electronic Temperature Control:

EXAIR’s digital ETC™ (Electronic Temperature Control) provides precise temperature control for your electrical enclosure. It can accurately maintain a constant temperature that is slightly under the maximum rating of the electronics, permitting just enough cooling for the electronics without going so cold as to waste compressed air.

The LED readout of the ETC displays the internal temperature of the electrical enclosure (°F or °C) that is constantly being monitored by a quick response thermocouple. The control activates the solenoid valve (included) when the temperature setting is exceeded. The polycarbonate plastic enclosure of the ETC is suitable for NEMA 12, 4 and 4X environments. (Cabinet Cooler not included.)

| Sample Rate | Max Temp | Solenoid Valve | Setting Temp | Supply Current | Sensor | |

| Model 9238 120VAC, 50-60 Hz | 1/sec. | 158°F (70°C) | 1/4 NPT | Push Button | 250 mA max | Type J Thermocouple |

| Model 9258 120VAC, 50-60 Hz | 1/sec. | 158°F (70°C) | 1/2 NPT | Push Button | 325 mA max | Type J Thermocouple |

| Model 9239 240VAC, 50-60 Hz | 1/sec. | 158°F (70°C) | 1/4 NPT | Push Button | 165 mA max | Type J Thermocouple |

| Model 9259 240VAC, 50-60 Hz | 1/sec. | 158°F (70°C) | 1/2 NPT | Push Button | 215 mA max | Type J Thermocouple |

ETC controls are available within Cabinet Cooler Systems or separately for retrofitting on existing coolers. ETCs are RoHS and CE compliant.

Selecting The Right Cabinet Cooler® System

With or Without Thermostat Control

EXAIR Cabinet Coolers are available with or without thermostat control. The continuous coolers (Model 4200 and 4700 series) are recommended when constant cooling and a constant positive purge are desirable. The thermostatically controlled systems (Model 4300 and 4800 series) save air by activating the cooler only when internal temperatures approach critical levels. The adjustable thermostat is factory set at 95°F (35°C). Thermostatic systems are recommended where heat load fluctuates and continual purge is not required.

All EXAIR Cabinet Cooler Systems contain a 5 micron Automatic Drain Filter for the compressed air supply and a Cold Air Distribution Kit to circulate the cold air throughout the enclosure.

Environmental Considerations

NEMA 12 (IP54) Cabinet Coolers (dust-tight, oil-tight) are ideal for general industrial environments where no liquids or corrosives are present.

NEMA 4 (IP66) Cabinet Coolers (dust-tight, oil-tight, splash resistant, indoor/outdoor service) incorporate a low pressure relief valve for both the vortex tube and cabinet air exhaust. This valve closes and seals when the cooler is not operating, to maintain the integrity of a NEMA 4 enclosure.

NEMA 4X (IP66) Cabinet Coolers (corrosion resistant) offer the same protection as NEMA 4, but are constructed of stainless steel for food service, pharmaceutical and corrosive environments.

Cabinet Cooler® Sizing Guide!

Use our Cabinet Cooler Sizing Guide to submit information online about your control panel cooling problem.

For immediate help, call our Application Engineering Department at 1-800-903-9247.

Cabinet Cooler Standards and Certifications

EXAIR's Cabinet Cooler Systems comply with OSHA's Safety Requirements, the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC). In addition, Cabinet Cooler Systems are Listed to applicable UL Standards and requirements by Underwriters' Laboratories. All sound level measurements are taken at 3 feet away.

Look for this symbol to designate conflict mineral free products throughout our website. EXAIR supports Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act and we are committed to compliance with the conflict minerals rule in order to curb the illicit trade of tin, tantalum, tungsten and gold in the DRC region. EXAIR is using the CMRT 3.02 template to document our supply chain and commitment to conflict free products.

Special Cabinet Coolers

EXAIR manufactures special NEMA 12 (IP54), 4 (IP66) and 4X (IP66) Cabinet Coolers suited to specific environmental requirements, as well as Side Mount Kits for mounting Cabinet Coolers on the side of enclosures. EXAIR Dual Cabinet Cooler Systems, High Temperature Cabinet Coolers, Non-Hazardous Purge Cabinet Coolers and Type 316 Cabinet Coolers are now available from stock.

EXAIR's Dual Cabinet Cooler Systems (shown left) are ideal for large electrical enclosures and high heat loads. Dual Cabinet Coolers are available with cooling capacities of 3,400 (997 Watts), 4,000 (1,171 Watts), 4,800 (1,406 Watts) and 5,600 Btu/hr. (1,641 Watts). For more information, contact an Application Engineer.

High Temperature Cabinet Cooler Systems for ambients of 125° to 200°F (52° to 93°C) are available (shown right). Internal components can withstand high temperatures (like those near furnaces, ovens, etc.) High Temperature Dual Cabinet Cooler Systems are also available.

Non-Hazardous Purge Cabinet Cooler Systems (shown left) are ideal for dirty areas where contaminants might normally pass through small holes or conduits. Under normal conditions, the NHP Cabinet Cooler System provides a slight positive pressure in the enclosure by passing 1 SCFM (28 SLPM) of air through the cooler, when the solenoid valve is in the closed position. When the thermostat detects high temperature, it energizes the solenoid valve to pass full line pressure to the Cabinet Cooler, giving it full cooling capability. The continuous purge of the NHP Cabinet Cooler System keeps dirt, heat and moisture out of the enclosure.

Type 316 Stainless Steel NEMA 4X Cabinet Cooler Systems (shown right) are suitable for food service, pharmaceutical, harsh and corrosive environments, and other applications where 316SS is preferred. Capacities from 650 to 5,600 Btu/hr. (191 to 1,641 Watts) are available.

EXAIR Dual Cabinet Coolers, High Temperature Cabinet Coolers, Non-Hazardous Purge Cabinet Coolers and Type 316 Cabinet Coolers are available from stock.

-

NHP Cabinet Coolers keep enclosures cool and create a positive purge to combat extremely dusty environments.

NHP Cabinet Coolers keep enclosures cool and create a positive purge to combat extremely dusty environments. -

Side Mount kits are available when space is limited and mounting on top of the enclosure is not an option.

Side Mount kits are available when space is limited and mounting on top of the enclosure is not an option. -

High Temperature Cabinet Cooler systems can be in environmental temperatures up to 200°F.

High Temperature Cabinet Cooler systems can be in environmental temperatures up to 200°F. -

NEMA 4 Cabinet Cooler systems with ETC provide internal temperature feedback and push button temperature adjustment.

NEMA 4 Cabinet Cooler systems with ETC provide internal temperature feedback and push button temperature adjustment. -

Dual Cabinet Cooler systems combat heat loads up to 5600 Btu/hr.

Dual Cabinet Cooler systems combat heat loads up to 5600 Btu/hr. -

NHP Cabinet Cooler systems are available with dual Cabinet Coolers to combat the highest heat loads.

NHP Cabinet Cooler systems are available with dual Cabinet Coolers to combat the highest heat loads. -

NHP Cabinet Cooler systems provide a slight positive pressure in the cabinet at all times.

NHP Cabinet Cooler systems provide a slight positive pressure in the cabinet at all times.