Model 8199 Gen4® Ionizing Point™ Only

Applications

- Winding

- Rewinding

- Slitting

- Neutralizing ducted air

- Labeling

- Form and fill

- Neutralizing static for print quality

Advantages

- Low cost

- Rapid static decay

- Shockless

- Non-radioactive

- Compact

Ionizing Point Models |

|||

Ionizing Points are available in two different model types:

|

|||

|

|

Ionizing Point |

Ionizing Point System |

|

| Model | 8199 | 8299 | |

Accessories

Power Supply - The Model 7960 selectable voltage Power Supply allows you to choose the input voltages of 115 VAC or 230 VAC. The modular cable with electromagnetic shielding protects sensitive electronics against electromagnetic interference while easing connections and routing. An integrated fuse on the primary protects against voltage spikes. Power Supplies are UL Component Recognized to U.S. and Canadian Standards, and are CE and RoHS compliant.

Ionizing Point Performance | |||

| Distance From Charged Surface | |||

| 0.50" (13mm) | 1" (25mm) | 2" (51mm) | |

Dissipates 5kV (seconds) | 0.12 | 0.18 | 0.24 |

Ionizing Point Specifications | |

| Power Supply | EXAIR Model 7960 or 7961 Power Supply (5kV) is required for Ionizing Point operation. Power supplies are equipped with a modular 6' (1.83m) power cord, lighted power switch, integrated fuse on the primary and (2) or (4) high voltage outlets. |

| Electrical | For use with 5 kVrms, 5 milliamperes (max) power supply |

| Electrical Hazard | Shockless (less than 40 microamperes short circuited). Do not use near flammable materials or gases. |

| Materials of Construction | |

| Metal parts | Stainless Steel |

| Plastic parts | UL rated 94 HB |

| Emitter | Stainless Steel |

| Maximum ambient temperature | 165°F (74°C) |

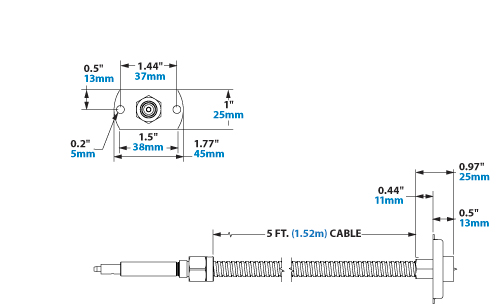

Ionizing Point Dimensions |

||||

|

How the Ionizing Point Works |

|

|

|

Static Eliminator Standards and Certifications

EXAIR's Gen4 Super Ion Air Knife complies with OSHA's Safety Requirements, the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC). All sound level measurements are taken at 3 feet away.

The Intellistat Ion Air Gun and Intellistat Ion Air Nozzle are UL Listed, and are CE and RoHS compliant.

Gen4 Ionizing Bars and Gen4 Power Supplies are UL Component Recognized to U.S. and Canadian safety standards, and are CE and RoHS compliant.

Look for this symbol to designate conflict mineral free products throughout our website. EXAIR supports Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act and we are committed to compliance with the conflict minerals rule in order to curb the illicit trade of tin, tantalum, tungsten and gold in the DRC region. EXAIR is using the CMRT 3.02 template to document our supply chain and commitment to conflict free products.

Selecting the Right EXAIR Static Eliminator

Static Eliminators with Air

Combining our engineered airflow products with ionizers gives us the ability to eliminate the charge quickly and at great distances. Laminar flow airstreams make it possible to blow away any contaminants and the charge that attracts them. They are ideal for:

- Hard to reach places or obstructed surfaces

- Product moving at high speeds

- Surfaces with an extremely high charge

Compressed air consumption and noise are minimized while providing force that can be adjusted from a “blast” to a “breeze”. Tests show these ionizers positioned two feet (610mm) away from a charged surface to be as effective as a Gen4 Ionizing Bar without air delivery positioned one-half inch (13mm) from the surface.

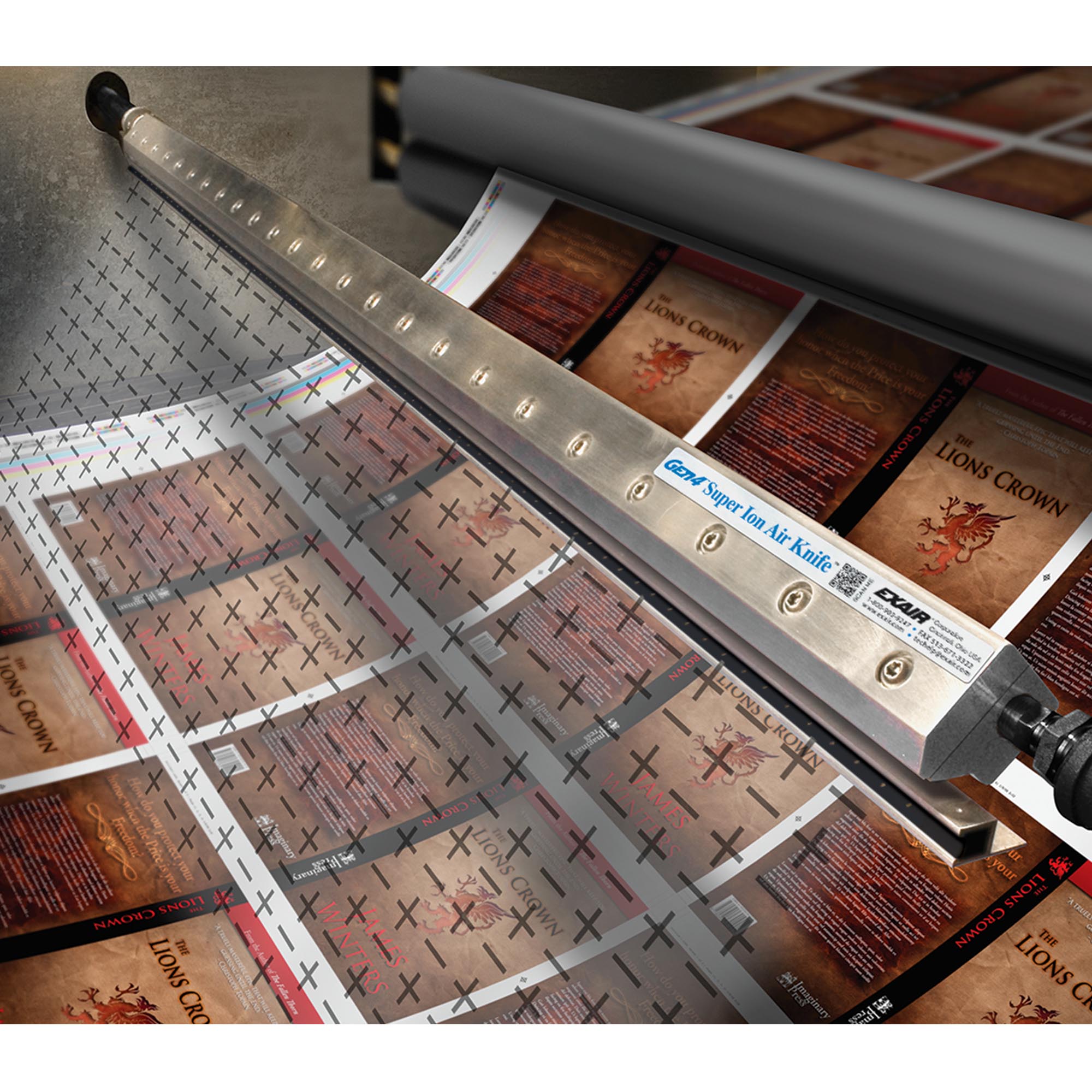

The Gen4 Super Ion Air Knife provides the best performance of all ionizers. It uses our Super Air Knife (40:1 air amplification) to deliver a uniform sheet of ionized air effective up to 20 feet (6.1m) away.

The Gen4 Standard Ion Air Knife uses our Standard Air Knife (30:1 air amplification) to deliver a sheet of ionized air to the surface. Air consumption and noise are somewhat higher than the Gen4 Super Ion Air Knife.

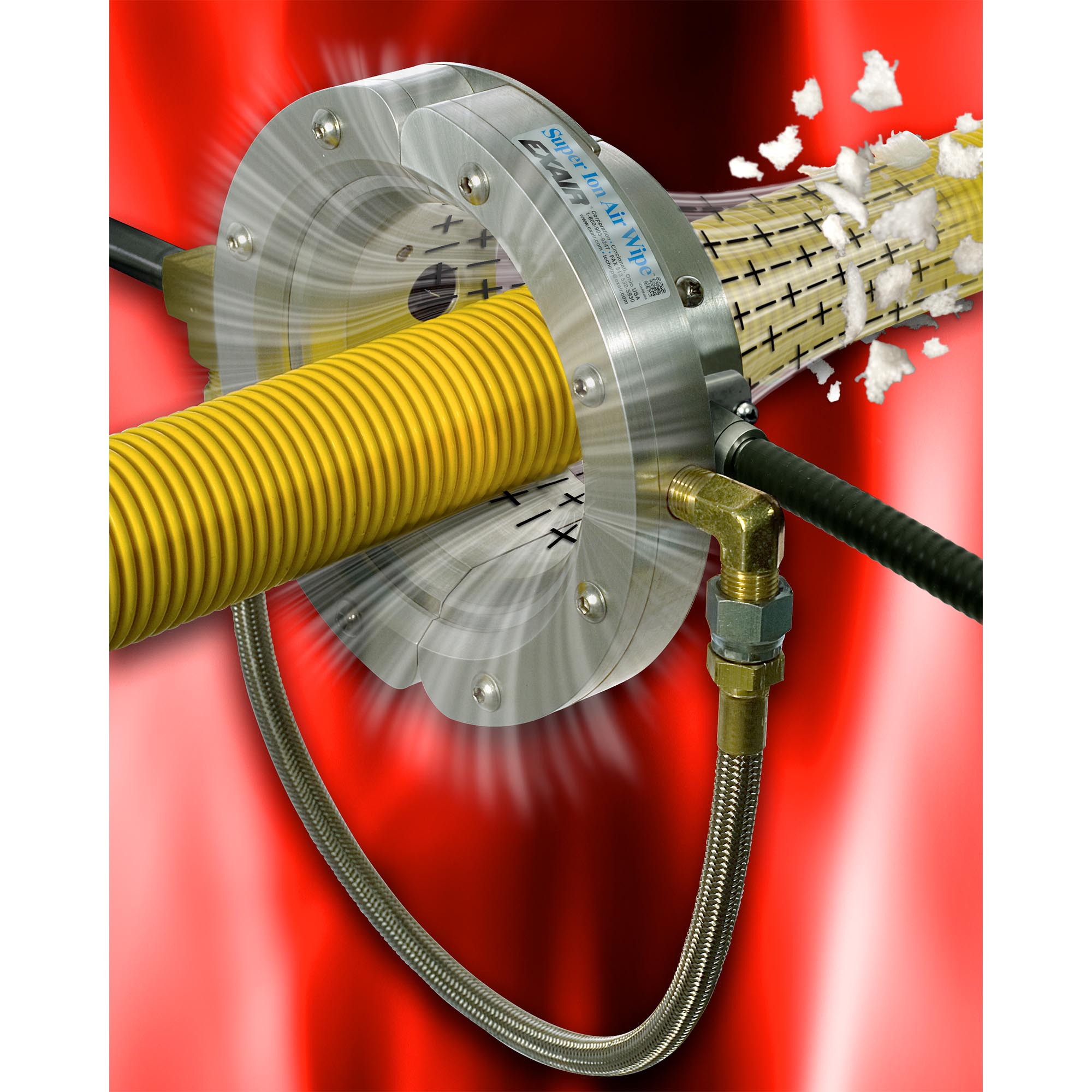

The Gen4 Super Ion Air Wipe clamps around the part and creates a ring of ionized airflow. It neutralizes and cleans continuous moving surfaces.

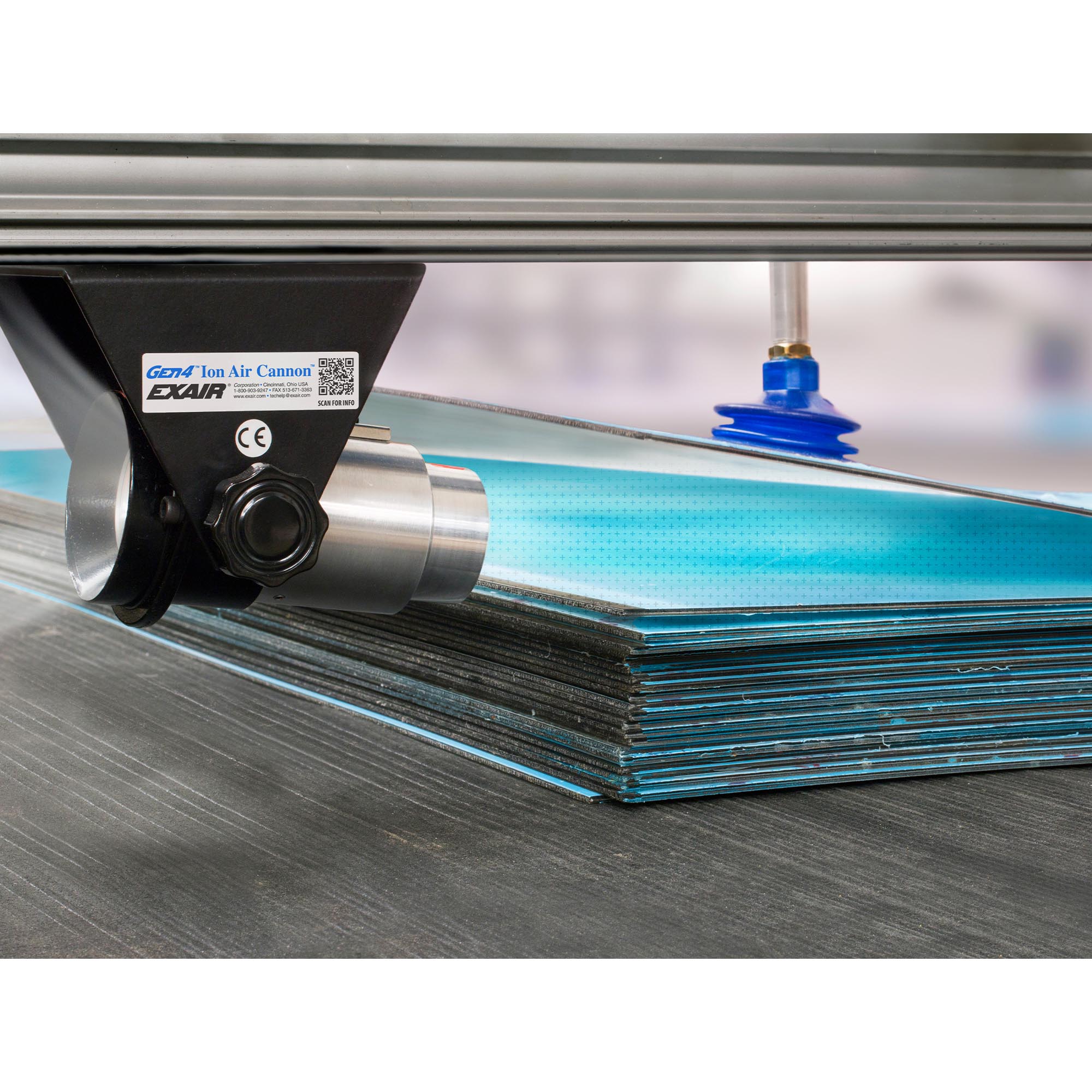

The Gen4 Ion Air Cannon uses our Super Air Amplifier (22:1 air amplification) to provide a focused, conical airstream that is capable of removing the charge up to 15 feet (4.6m) away.

The new patented Intellistat Ion Air Gun produces ionized compressed air to neutralize static and remove troublesome particulates during clean processes, test procedures and sensitive assembly work, particularly in laboratories, clean rooms or scientific testing facilities. With a +/-30 volt balance the Intellistat was designed to use minimal compressed air while delivering precise blow-off and exceptional static decay rates capable of reducing 5000 volts to less than 500 in under one second.

The new patented Intellistat Ion Air Nozzle produces ionized compressed air to neutralize static and remove troublesome particulates during clean processes, test procedures and sensitive assembly work, particularly in laboratories, clean rooms or scientific testing facilities. With a +/-30 volt balance the hands-free Intellistat was designed to use minimal compressed air while delivering precise blow-off and exceptional static decay rates capable of reducing 1000 volts to less than 100 in under one second.

The Gen4 Ion Air Gun uses our High Velocity Air Jet (5:1 air amplification) to provide a narrow beam of ionized airflow. This hand-held static eliminator is rugged for industrial use and has incredibly fast static decay rates.

The Gen4 Ion Air Jet uses our High Velocity Air Jet (5:1 air amplification), and is an effective spot cleaner. Available for permanent mount or with flexible Stay Set Hose, this ionizer is the ideal way to focus an ionized airflow at confined areas.

Static Eliminators without Air

In some situations, even the smallest amount of airflow can disturb the product. This is especially true for lightweight materials. EXAIR manufactures two styles of ionizers for these critical applications.

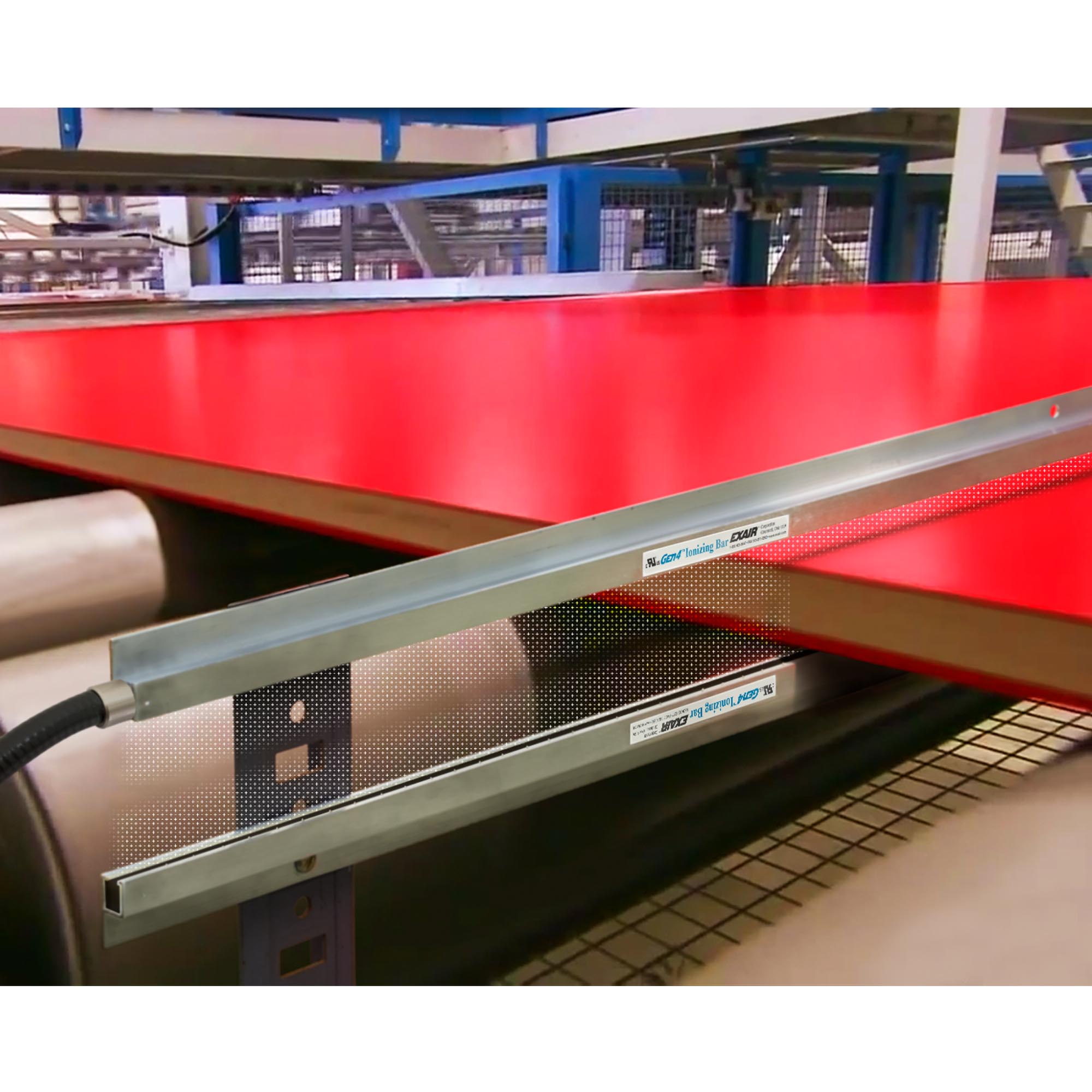

Gen4 Ionizing Bars are ideal for relatively flat materials, where the bar can be mounted close to the product surface. The Gen4 Ionizing Bar is compact, allowing it to fit in the confined spaces of machinery, where the charge is generated.

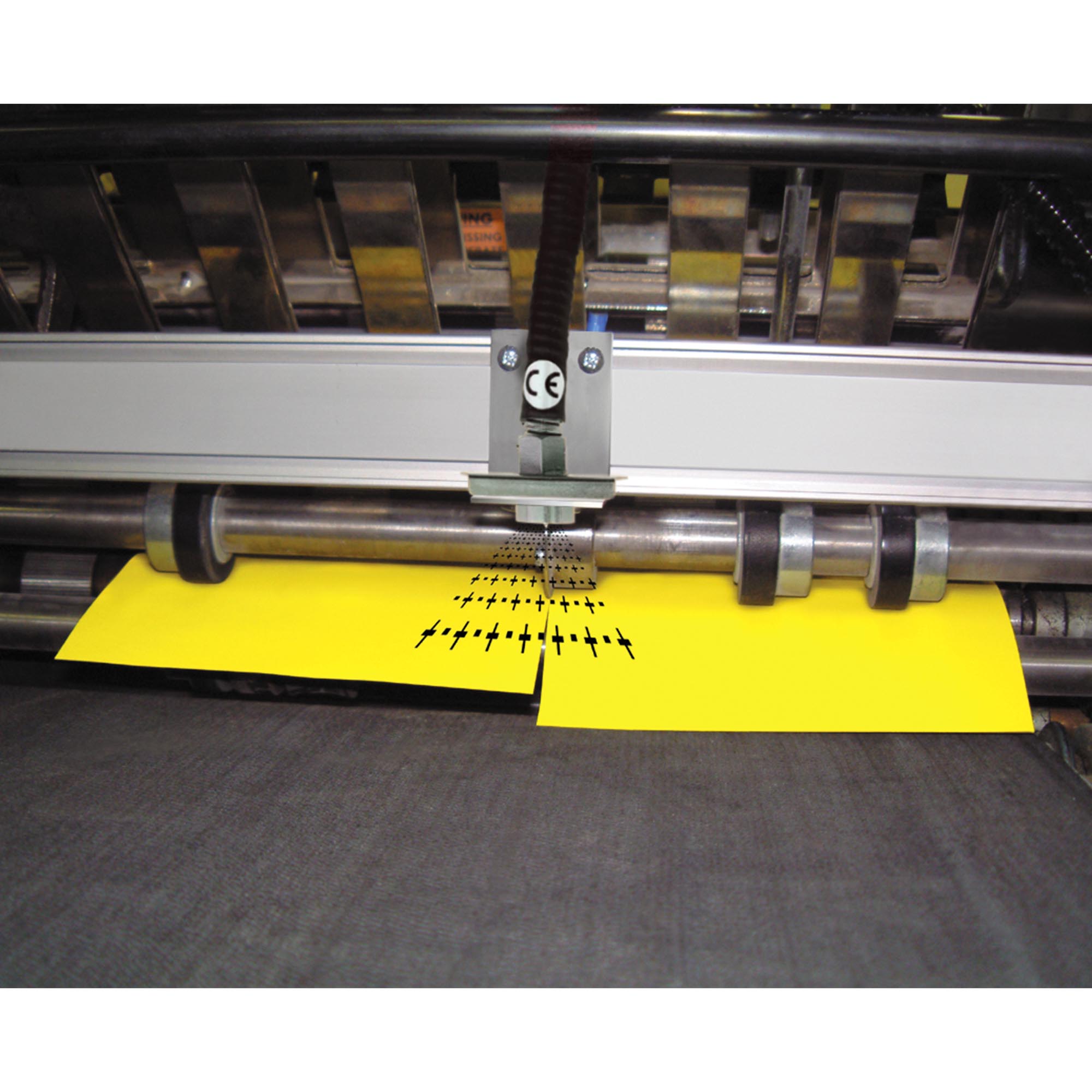

The Gen4 Ionizing Point is effective for spot neutralization. The compact size makes it ideal for winding or slitting operations. It can also be mounted through a duct to neutralize static charges due to moving air or materials.

Special Static Eliminators

EXAIR manufactures static eliminators suited to specific application requirements. This special ionizer was developed for the automotive industry. This air amplifier and ionizer combination is used to dry water based paints on car bodies while eliminating the possibility of a static charge that might attract dust or other contaminants.

-

Model 8199 Gen4 Ionizing Point

Model 8199 Gen4 Ionizing Point -

This Gen4 Ionizing Point removes static from a card slitting operation.

This Gen4 Ionizing Point removes static from a card slitting operation. -

This Gen4 Ionizing Point removes static from a paper slitting operation.

This Gen4 Ionizing Point removes static from a paper slitting operation. -

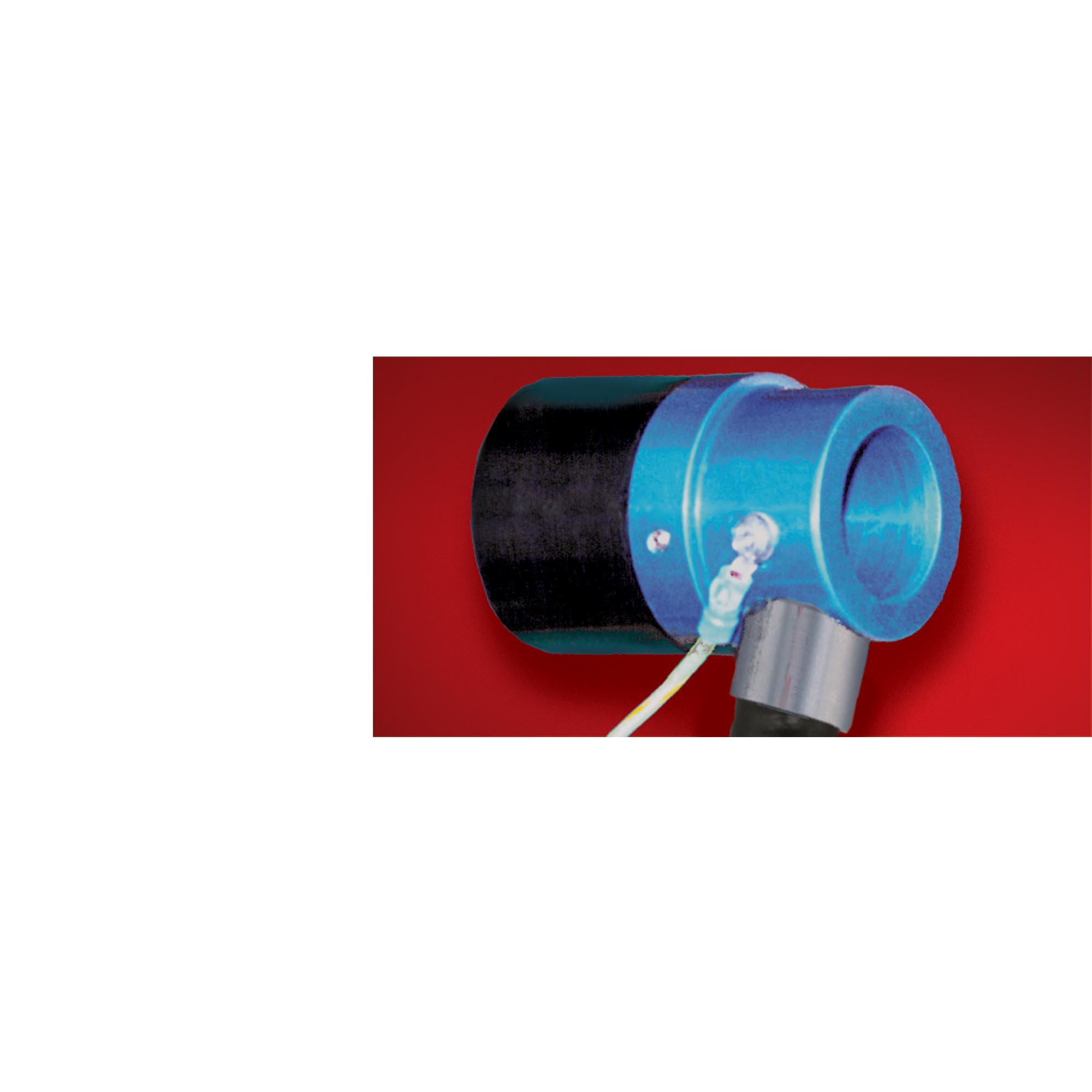

Model 8299 includes the two outlet Power Supply

Model 8299 includes the two outlet Power Supply