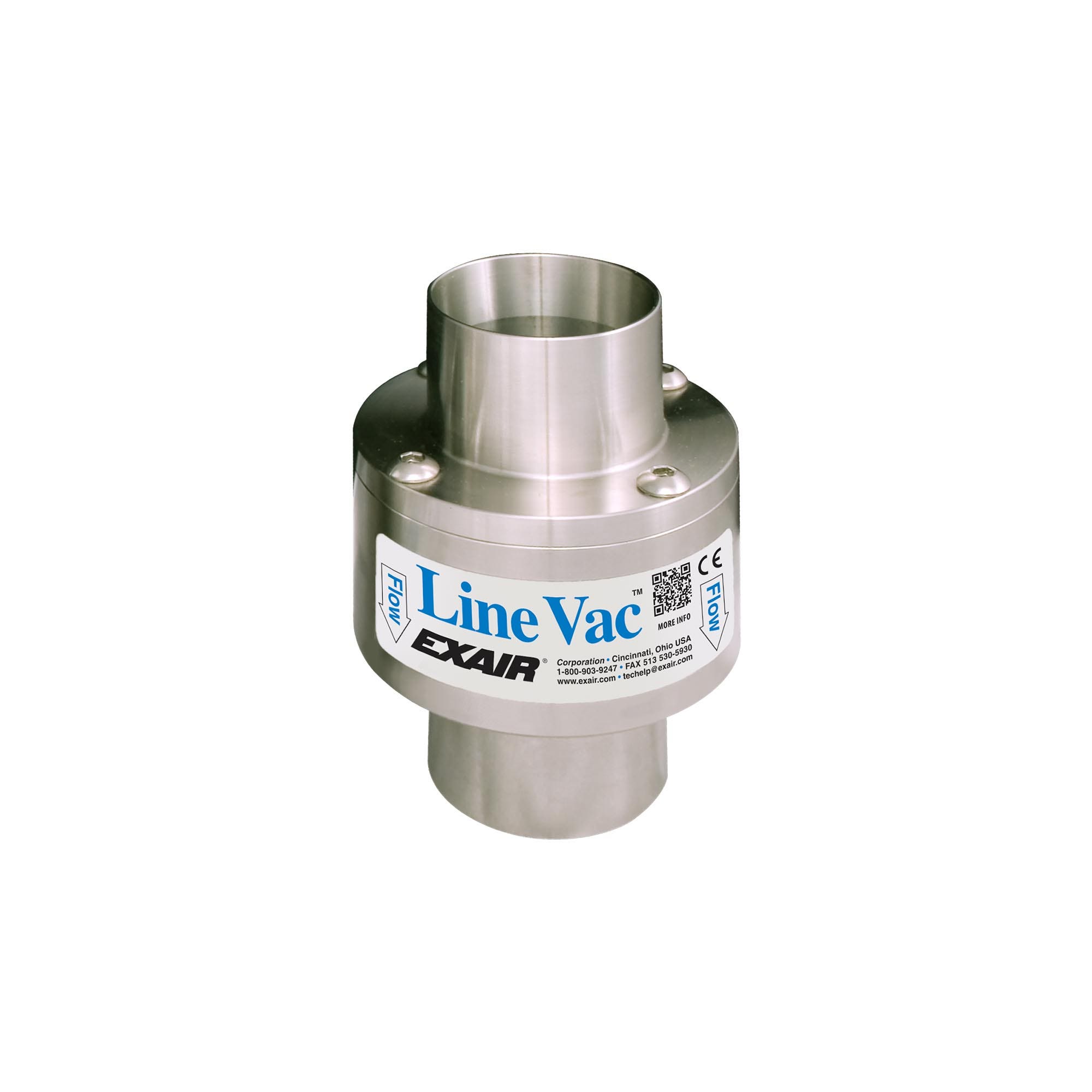

Model 151250 2-1/2 NPT Heavy Duty Threaded Line Vac

Applications

- Hopper loading

- Fiber tensioning

- Material conveying

- Waste/trim removal

- Chip removal

- Part transfer

- Filling operations

Advantages

- Hardened alloy construction

- Highest throughput capability

- Compact

- Quiet

- No moving parts

- Attaches to ordinary pipe and fittings

- Available from stock

Heavy Duty Threaded Line Vac Models

Heavy Duty Threaded Line Vacs are available individually and in kits. Heavy Duty Threaded Line Vac Kits include a Heavy Duty Threaded Line Vac, filter separator and pressure regulator (with coupler).

Accessories

Mounting Brackets - are available for Line Vacs from 3/8" (10mm) through 3" (76mm).

Drum Covers - EXAIR's fine mesh non-woven Drum Cover is built to fit over the top of 55 or 30 gallon drums. It is suitable for Line Vac conveyance hoses from 3/4" through 3.4" outside diameters and comes complete with hose clamps and a durable spring buckle strap for quick and easy installation.

Line Vac Model Comparison |

||

| Material Type | Temperature Rating | Corrosion Resistance |

| Aluminum Line Vac | 275°F (135°C) | Fair |

| Stainless Steel Line Vac (Type 303) | 400°F (204°C) | Good |

| Stainless Steel Line Vac (Type 316) | 400°F (204°C) | Excellent |

| Stainless Steel Flanged Line Vac (Type 316) | 400°F (204°C) | Excellent |

| High Temperature Stainless Steel Line Vac (Type 303) | 900°F (482°C) | Good |

| High Temperature Stainless Steel Line Vac (Type 316) | 900°F (482°C) | Excellent |

| Heavy Duty Line Vac Hardened Alloy Construction | 400°F (204°C) | Good |

Sizes

Heavy Duty Threaded Line Vacs are available in a wide range of sizes from 3/4 NPT to 3 NPT to fit your application. Some of the criteria used to select the proper model are:

- Diameter of parts being conveyed

- Diameter of hose or tube

- Rate (weight or volume)

Line Vac Styles

Six styles are available:

Line Vac is designed to fit standard hose and tube. They are best for moving materials over long horizontal and vertical distances. Eleven sizes in aluminum and ten sizes in stainless steel are available to suit a wide variety of transfer applications. Models in Type 316 stainless steel (for corrosion, food and pharmaceutical) as well as models for high temperature are also available.

Threaded Line Vac attaches easily to plumbing pipe couplers, making it easy to build a complete conveying system using pipes and fittings available at any home center, hardware store or plumbers supply. Nine sizes up to 3 NPT are available in aluminum, stainless steel and for high temperature.

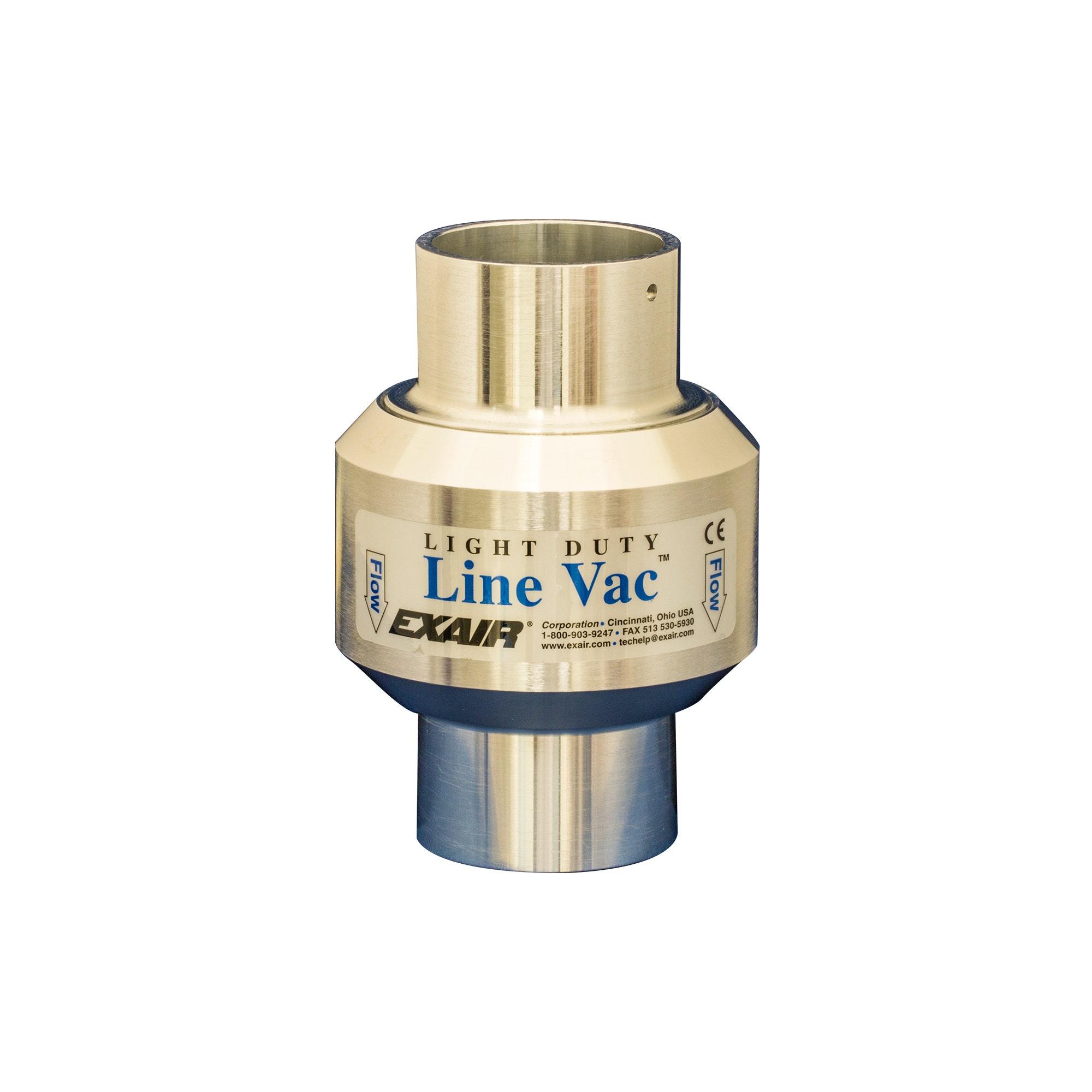

Light Duty Line Vac is perfect for conveying small amounts of material over short distances. This simplified design utilizes a two-part threaded construction to provide effective conveying at a lower cost. Air consumption is reduced to a volume appropriate for moving small volumes of material at short distances. Eight sizes up to 6" (152mm) in aluminum are available.

Heavy Duty Line Vac is the most powerful Line Vac that moves high volumes of material. The hardened alloy construction helps prevent wear that could occur with ordinary aluminum or stainless steel Line Vacs. Seven sizes up to 3" (76mm) are available. Heavy Duty Threaded Line Vac models available also.

High Temperature Line Vacs are suited for temperatures up to 900°F (482°C). Frequently used for sampling hot flue gases, the High Temperature Line Vac can resist back pressure from long pipe lengths with numerous bends.

Sanitary Flange Line Vacs are the best way to convey materials in systems which require frequent or mandatory cleaning. Four sizes from 1-1/2" to 3" are available in Type 316 stainless steel. ISO 2852 compatible.

Heavy Duty Threaded Line Vac Performance |

||||||

| 80 PSIG (5.5 BAR) | Size | Air Consumption | Vacuum | |||

| Model # | in | mm | SCFM | SLPM | "H2O | kPa |

| 151075 | 0.75 | 19 | 26 | 736 | -144 | -36 |

| 151100 | 1 | 25 | 35 | 991 | -105 | -26 |

| 151125 | 1.25 | 32 | 49 | 1,388 | -83 | -21 |

| 151150 | 1.50 | 38 | 55 | 1,557 | -60 | -15 |

| 151200 | 2 | 51 | 75 | 2,124 | -42 | -10 |

| 151250 | 2.50 | 64 | 90 | 2,548 | -28 | -7 |

| 151300 | 3 | 76 | 108 | 3,058 | -20 | -5 |

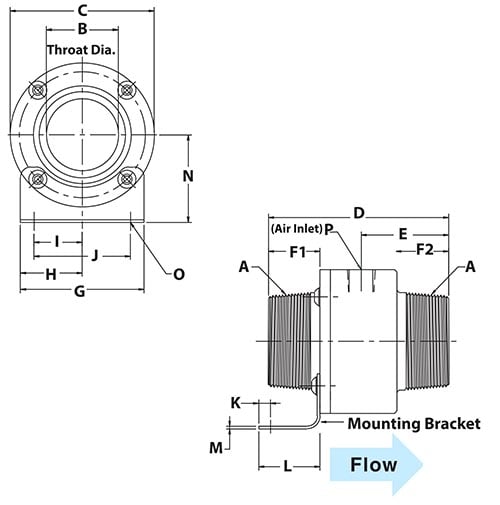

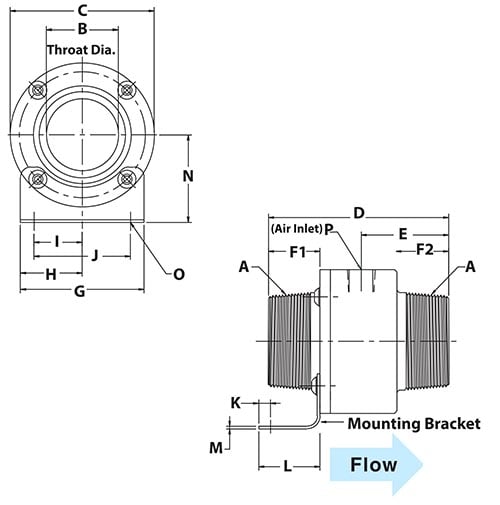

Heavy Duty Threaded Line Vac Dimensions |

||||||||

|

||||||||

Models |

Model Numbers |

|||||||

| Heavy Duty Threaded Line Vac | 151075 | 151100 | 151125 | 151150 | 151200 | 151250 | 151300 | |

| A (Hose Size) | in | 0.75 | 1 | 1.25 | 1.50 | 2 | 2.50 | 3 |

| mm | 19 | 25 | 32 | 38 | 51 | 64 | 76 | |

| B | in | 0.50 | 0.75 | 1 | 1.25 | 1.75 | 2.25 | 2.75 |

| mm | 13 | 19 | 25 | 32 | 45 | 57 | 70 | |

| C | in | 1.88 | 2.13 | 2.38 | 2.75 | 3.25 | 3.75 | 4.25 |

| mm | 48 | 54 | 61 | 70 | 83 | 95 | 108 | |

| D | in | 3.88 | 3.88 | 3.88 | 4.38 | 4.38 | 4.38 | 5.63 |

| mm | 99 | 99 | 99 | 111 | 111 | 111 | 143 | |

| E | in | 1.88 | 1.88 | 1.88 | 2.13 | 2.13 | 2.13 | 2.75 |

| mm | 48 | 48 | 48 | 54 | 54 | 54 | 70 | |

| F | in | 1 | 1 | 1 | 1.25 | 1.25 | 1.25 | 1.75 |

| mm | 25 | 25 | 25 | 32 | 32 | 32 | 45 | |

| G | in | 2 | 2 | 2.50 | 2.50 | 3 | 3 | 3.25 |

| mm | 51 | 51 | 64 | 64 | 76 | 76 | 83 | |

| H | in | 1 | 1 | 1.25 | 1.25 | 1.50 | 1.50 | 1.63 |

| mm | 25 | 25 | 32 | 32 | 38 | 38 | 41 | |

|

||||||||

Models |

Model Numbers |

|||||||

| Heavy Duty Threaded Line Vac | 151075 | 151100 | 151125 | 151150 | 151200 | 151250 | 151300 | |

| I | in | 0.76 | 0.65 | 1 | 0.86 | 1.17 | 1 | 1.20 |

| mm | 19 | 17 | 25 | 22 | 30 | 25 | 31 | |

| J | in | 1.52 | 1.30 | 2 | 1.73 | 2.34 | 2 | 2.41 |

| mm | 39 | 33 | 51 | 44 | 59 | 51 | 61 | |

| K | in | 0.25 | 0.26 | 0.31 | 0.25 | 0.28 | 0.31 | 0.41 |

| mm | 6 | 7 | 8 | 6 | 7 | 8 | 10 | |

| L | in | 1.38 | 1.32 | 1.61 | 1.44 | 1.48 | 1.44 | 1.44 |

| mm | 35 | 34 | 41 | 37 | 38 | 37 | 37 | |

| M | in | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 | 0.06 |

| mm | 2 | 2 | 2 | 2 | 2 | 2 | 2 | |

| N | in | 1.44 | 1.56 | 1.68 | 1.88 | 2.13 | 2.38 | 2.63 |

| mm | 37 | 40 | 43 | 48 | 54 | 60 | 67 | |

| O | in | 0.20 | 0.20 | 0.28 | 0.28 | 0.28 | 0.28 | 0.28 |

| mm | 5 | 5 | 7 | 7 | 7 | 7 | 7 | |

| P | 1/4 FNPT | 1/4 FNPT | 1/4 FNPT | 3/8 FNPT | 3/8 FNPT | 3/8 FNPT | 1/2 FNPT | |

Compressed air flows through the inlet (1) into an annular plenum chamber (2). It is then injected into the throat through directed nozzles (3). These jets of air create a vacuum at the intake (4) which draws material in and accelerates it through the unit (5) for conveying over long vertical or horizontal distances.

Line Vac Standards and Certifications

EXAIR Line Vacs comply with OSHA's Safety Requirements, the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC). All sound level measurements are taken at 3 feet away.

Look for this symbol to designate conflict mineral free products throughout our website. EXAIR supports Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act and we are committed to compliance with the conflict minerals rule in order to curb the illicit trade of tin, tantalum, tungsten and gold in the DRC region. EXAIR is using the CMRT 3.02 template to document our supply chain and commitment to conflict free products.

Infinite control of the flow rate through the Line Vac can be controlled by a pressure regulator. Kits include a pressure regulator that is sized properly for flow. The actual conveying rate is affected by the size, mass and geometry of the part to be conveyed along with the length, lift and number of bends in the hose, tube or pipe. These variables make it difficult to determine the exact conveying rate for any product, however, our Application Engineers can assist you by comparing the material you want to convey with something that has already been tested.

Many applications require that materials be transported over longer distances. The Heavy Duty Line Vac can move more material over longer lengths. They have been designed for rugged, industrial applications.

The table below gives a quick comparison of our Light Duty Line Vac, standard Line Vac and the Heavy Duty Line Vac models. For comparison, the test shows the 2" (51mm) model of each style conveying the same material over various lengths. Heavy Duty Line Vac conveys more material in less time.

Rock Salt Conveying Rate Comparison |

||

| Model | 100 Feet (30.5m) | 200 Feet (61m) |

| Model 130200 2" (51mm) Light Duty Line Vac | 166 lbs/hr. (75.3 kg/hr.) | N/A |

| Model 6084 2" (51mm) Line Vac | 334 lbs/hr. (151.5 kg/hr.) | 85 lbs/hr. (38.6 kg/hr.) |

| Model 150200 2" (51mm) Heavy Duty Line Vac | 524 lbs/hr. (237.7 kg/hr.) | 200 lbs/hr. (90.7 kg/hr.) |

| Horizontal conveying tested at 80 PSIG (5.5 BAR). | ||

Special Line Vacs

EXAIR manufactures special Line Vacs suited to specific application requirements. Configurations and materials can vary according to the application requirements.

Line Vac can be engineered to retrofit existing machinery. The Line Vac (shown right) has special flanges that permit direct mounting to a machine used in the manufacturing of silicon wafers for the semiconductor industry. This flanged Line Vac is used to remove acidic vapors resulting from surface etching of a silicon wafer. Ordinarily, EXAIR’s Stainless Steel Air Amplifier would have been used since it moves much higher volumes of air. In this case, the Line Vac was the better choice since the exhaust piping was long with many bends that would have created high back pressure. The directed nozzles of the Line Vac overcame this downstream resistance.

Filling small packets with fine powders or granulated materials such as salt or barite is done using small tubes that are gravity fed from a hopper. This works well when the material is dry, however, moist materials would often pack the tube, blocking the flow. The special funnel shaped Line Vac (shown right) created a suction on the existing tube to permit continuous product flow.

The special flanged Line Vac (shown right) is made of PVDF, a plastic that has a high chemical resistance. In this case, the 1-1/2" (38mm) Line Vac was regularly exposed to a chloride wash, a chemical that would corrode stainless steel. QF flanges were provided on each end to allow easy removal of the conveying hoses for cleaning purposes.

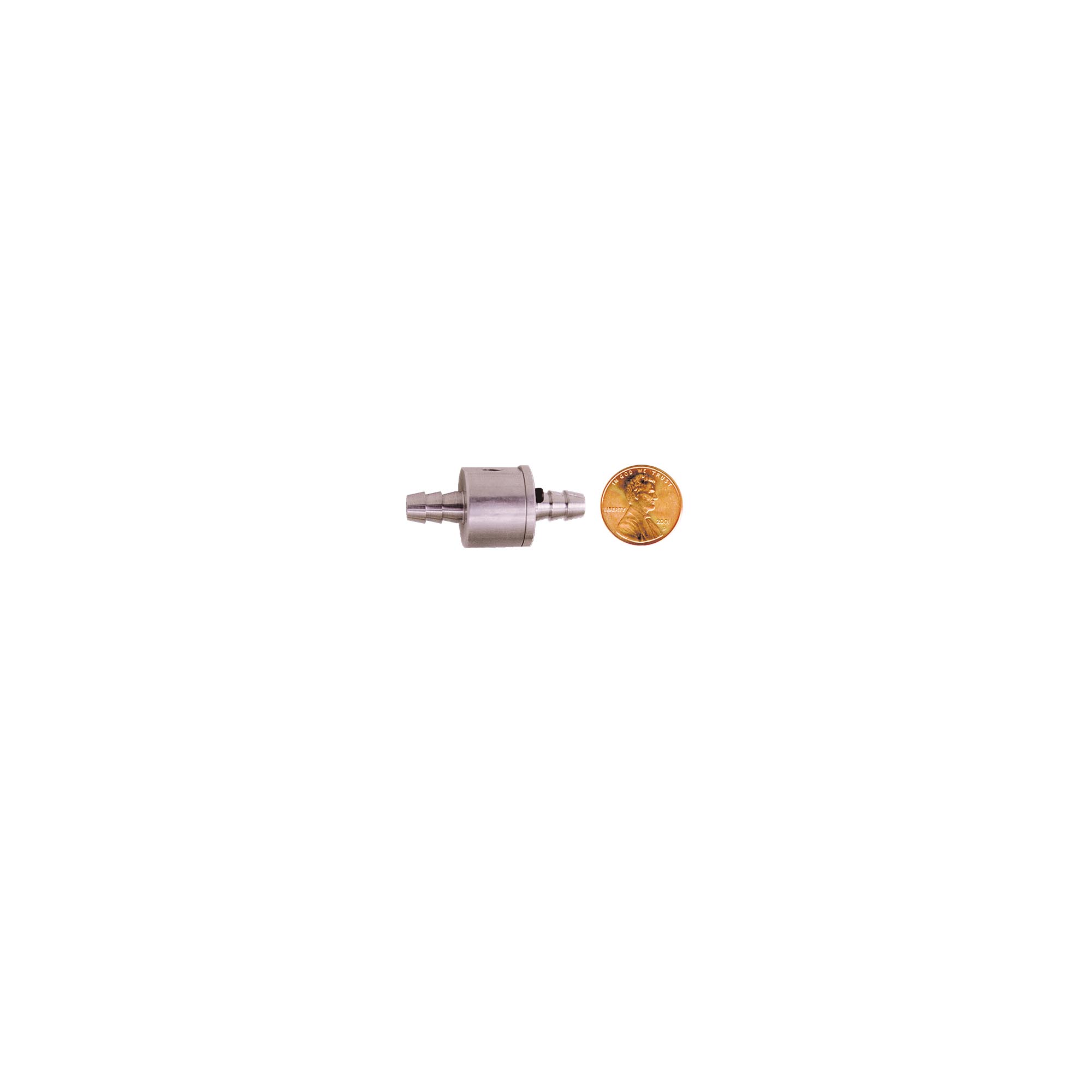

The special miniature Line Vac with barb fittings (shown right) was designed for a manufacturer of integrated circuit chips. It was used to remove microscopic debris during the chip making process. This small Line Vac generated high vacuum and was the perfect configuration for the confined working space. It has also been used by another manufacturer to vacuum liquid and chips from small drilled holes.

-

Model 151250 2-1/2 NPT Heavy Duty Threaded Line Vac

Model 151250 2-1/2 NPT Heavy Duty Threaded Line Vac

| Material | Hardened Alloy |

|---|