Model 3725 Adjustable Spot Cooler only

Applications

- Adjusting thermostats

- Cooling solder

- Cooling machined plastics

- Setting hot melts

- Cooling welding horns

- Cooling molded plastics

- Electronic component cooling

- Cooling gas samples

- Cooling environmental chambers

Advantages

- No moving parts

- No electricity or chemicals

- Small, lightweight

- Low cost

- Maintenance free

- Instant cold air

- Quiet - less than 75 dBA

- Swivel magnetic base

- Interchangeable generators

Accessories |

|

| Model | Description |

| 5901 | Single Point Hose Kit (Included with 3825) |

| 5902 | Dual Point Hose Kit (Included with 3925) |

| 9004 | Auto Drain Filter Separator, 1/4 NPT, 43 SCFM (1,359 SLPM) (included with 3825 and 3925) |

| 9012 | Manual Shutoff Valve, 1/4 NPT |

| 9020 | Solenoid Valve, 120V, 50/60Hz, 1/4 NPT, 40 SCFM (1,133 SLPM) |

Adjustable Spot Cooler Systems

Two systems are available:

Model 3825 Adjustable Spot Cooler System - includes the Adjustable Spot Cooler, single point hose kit with cone and fan nozzle, swivel magnetic base, filter separator, 15 and 30 SCFM (425 and 850 SLPM) generators. (25 SCFM/708 SLPM generator installed.)

Model 3925 Adjustable Spot Cooler System includes the Adjustable Spot Cooler, dual point hose kit with cone and fan nozzles, swivel magnetic base, filter separator, 15 and 30 SCFM (425 and 850 SLPM) generators. (25 SCFM/708 SLPM generator installed.) (Adjustable Spot Cooler with dual point hose kit is recommended when heat is generated over a larger surface area.)

Adjustable Spot Cooler Specifications |

||||

| Pressure Supply | Air Consumption | Sound @ 3' (914mm) | ||

| PSIG | BAR | SCFM | SLPM | dBA |

| 100 | 6.9 | 15 | 425 | 76 |

| 100 | 6.9 | 25* | 708 | 73 |

| 100 | 6.9 | 30 | 850 | 74 |

|

*25 SCFM (708 SLPM) generator is factory installed. Air consumption is based on generator installed. |

||||

Adjusting the Spot Cooler

The Adjustable Spot Cooler System can produce a full range of airflows and temperatures as determined by the knob setting and a small internal part called a generator. The generators control the SCFM (SLPM) of air consumption and are easily interchangeable. The Adjustable Spot Cooler has a 25 SCFM (708 SLPM) generator installed that produces up to 1,700 Btu/hr. (498 Watts). If less cooling is desired, the 15 SCFM (425 SLPM) generator, which delivers 1,000 Btu/hr. (293 Watts), can be installed. If more cooling is needed, the 30 SCFM (850 SLPM) generator can be installed for up to 2,000 Btu/hr. (586 Watts).

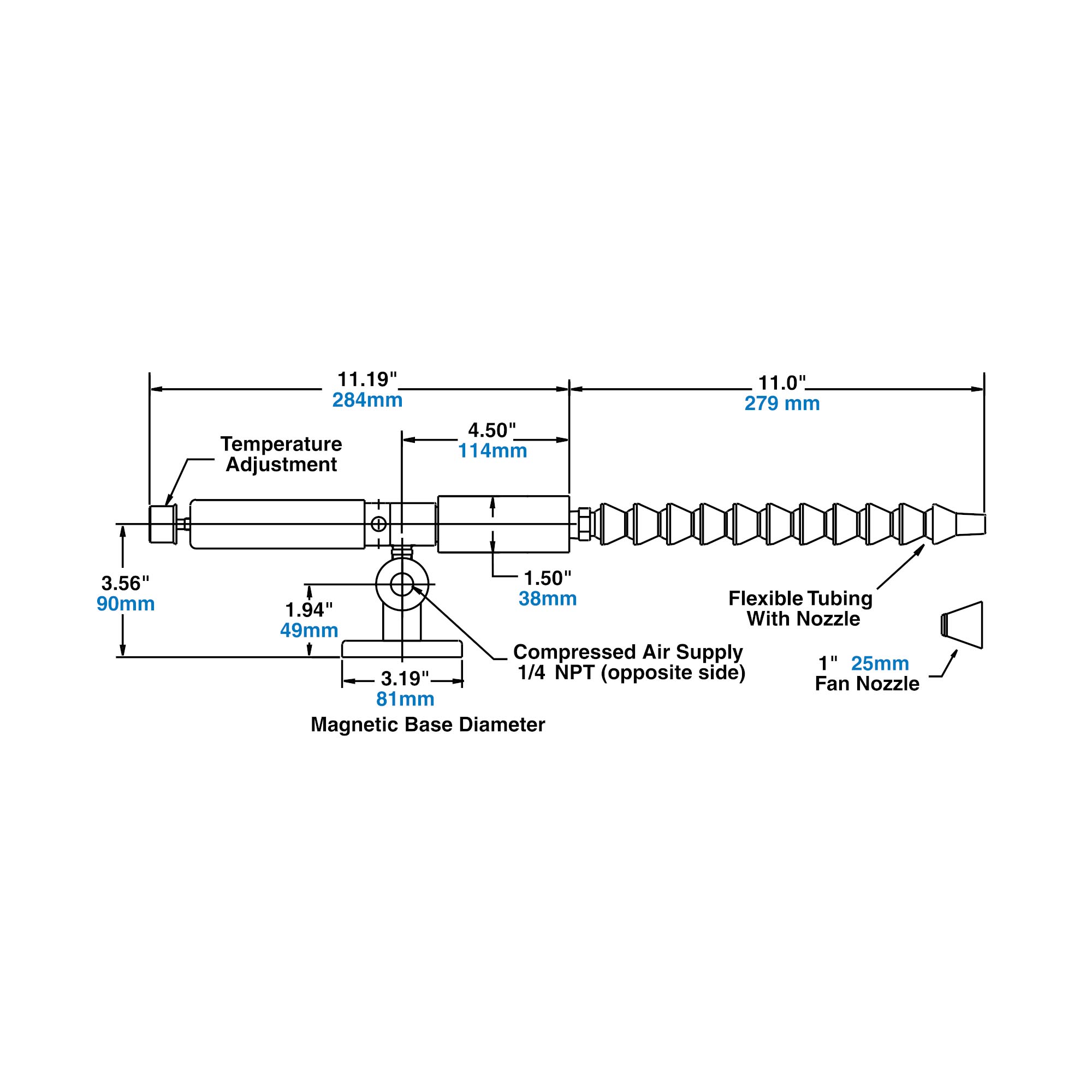

Adjustable Spot Cooler Dimensions |

|

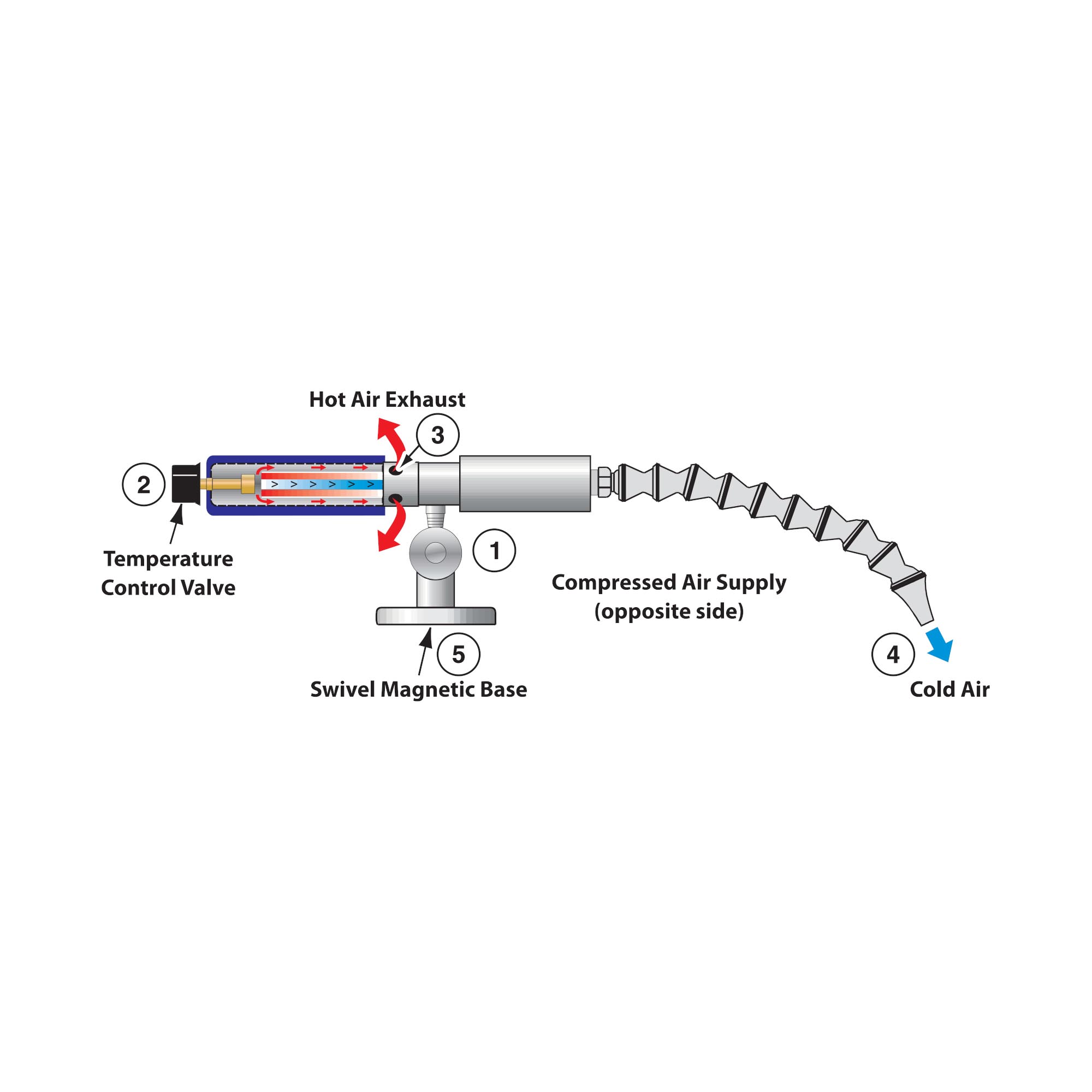

How the Adjustable Spot Cooler Works |

|

|

The Adjustable Spot Cooler incorporates a vortex tube to convert an ordinary supply of compressed air (1) into two low pressure streams, one hot and one cold. With the turn of a knob, the temperature control valve (2) allows some hot air to flow through a muffling sleeve and out the hot air exhaust (3). The opposite end provides a cold airstream (4) that is muffled and discharged through the flexible hose, which directs it to the point of use. The swivel magnetic base (5) provides easy mounting and portability. |

Controlling the Cold Air

The Adjustable Spot Cooler gives instant cold air when filtered compressed air is supplied to it. Cycling on and off is a good way to save air. For on and off control, use a Model 9012 Manual Shutoff Valve. To turn the Adjustable Spot Cooler on with the machine, the Model 9020 Solenoid Valve may be used and wired through the machine control switch. The EFC electronic flow control can also be used.

Adjustable Spot Cooler Standards and Certifications

EXAIR Adjustable Spot Coolers comply with OSHA's Safety Requirements, the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC). All sound level measurements are taken at 3 feet away.

Look for this symbol to designate conflict mineral free products throughout our website. EXAIR supports Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act and we are committed to compliance with the conflict minerals rule in order to curb the illicit trade of tin, tantalum, tungsten and gold in the DRC region. EXAIR is using the CMRT 3.02 template to document our supply chain and commitment to conflict free products.

A Phenomenon of Physics

The two questions we’re most often asked about the vortex tube are, “How long has it been around?” and “How does the thing work?” The following is a brief history and theory of the vortex tube.

The vortex tube was invented quite by accident in 1928. George Ranque, a French physics student, was experimenting with a vortex-type pump he had developed when he noticed warm air exhausting from one end, and cold air from the other. Ranque soon forgot about his pump and started a small firm to exploit the commercial potential for this strange device that produced hot and cold air with no moving parts. However, it soon failed and the vortex tube slipped into obscurity until 1945 when Rudolph Hilsch, a German physicist, published a widely read scientific paper on the device.

Much earlier, the great nineteenth century physicist, James Clerk Maxwell, postulated that since heat involves the movement of molecules, we might someday be able to get hot and cold air from the same device with the help of a “friendly little demon” who would sort out and separate the hot and cold molecules of air.

Thus, the vortex tube has been variously known as the “Ranque Vortex Tube”, the “Hilsch Tube”, the “Ranque-Hilsch Tube”, and “Maxwell’s Demon”. By any name, it has in recent years gained acceptance as a simple, reliable and low cost answer to a wide variety of industrial spot cooling problems.

A vortex tube uses compressed air as a power source, has no moving parts, and produces hot air from one end and cold air from the other. The volume and temperature of these two airstreams are adjustable with a valve built into the hot air exhaust. Temperatures as low as -50°F (-46°C) and as high as +260°F (+127°C) are possible.

Theories abound regarding the dynamics of a vortex tube. Here is one widely accepted explanation of the phenomenon:

Compressed air is supplied to the vortex tube and passes through nozzles that are tangential to an internal counterbore. These nozzles set the air in a vortex motion. This spinning stream of air turns 90° and passes down the hot tube in the form of a spinning shell, similar to a tornado. A valve at one end of the tube allows some of the warmed air to escape. What does not escape, heads back down the tube as a second vortex inside the low-pressure area of the larger vortex. This inner vortex loses heat and exhausts through the other end as cold air.

While one airstream moves up the tube and the other down it, both rotate in the same direction at the same angular velocity. That is, a particle in the inner stream completes one rotation in the same amount of time as a particle in the outer stream. However, because of the principle of conservation of angular momentum, the rotational speed of the smaller vortex might be expected to increase. (The conservation principle is demonstrated by spinning skaters who can slow or speed up their spin by extending or drawing in their arms.) But in the vortex tube, the speed of the inner vortex remains the same. Angular momentum has been lost from the inner vortex. The energy that is lost shows up as heat in the outer vortex. Thus the outer vortex becomes warm, and the inner vortex is cooled.

-

Model 3725 Adjustable Spot Cooler

Model 3725 Adjustable Spot Cooler