High Velocity Air Jet Shim Set

Adjustable Air Jet Materials

Brass - general purpose applications. Maximum temperature 400°F (204°C).

Type 303 Stainless Steel - high temperatures, corrosive environments. Maximum temperature 800°F (426°C)

Adjustable Air Jet Standards and Certifications

EXAIR Adjustable Air Jets comply with OSHA's Safety Requirements, the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC). All sound level measurements are taken at 3 feet away.

Look for this symbol to designate conflict mineral free products throughout our website. EXAIR supports Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act and we are committed to compliance with the conflict minerals rule in order to curb the illicit trade of tin, tantalum, tungsten and gold in the DRC region. EXAIR is using the CMRT 3.02 template to document our supply chain and commitment to conflict free products.

Safe and Efficient Use of Compressed Air

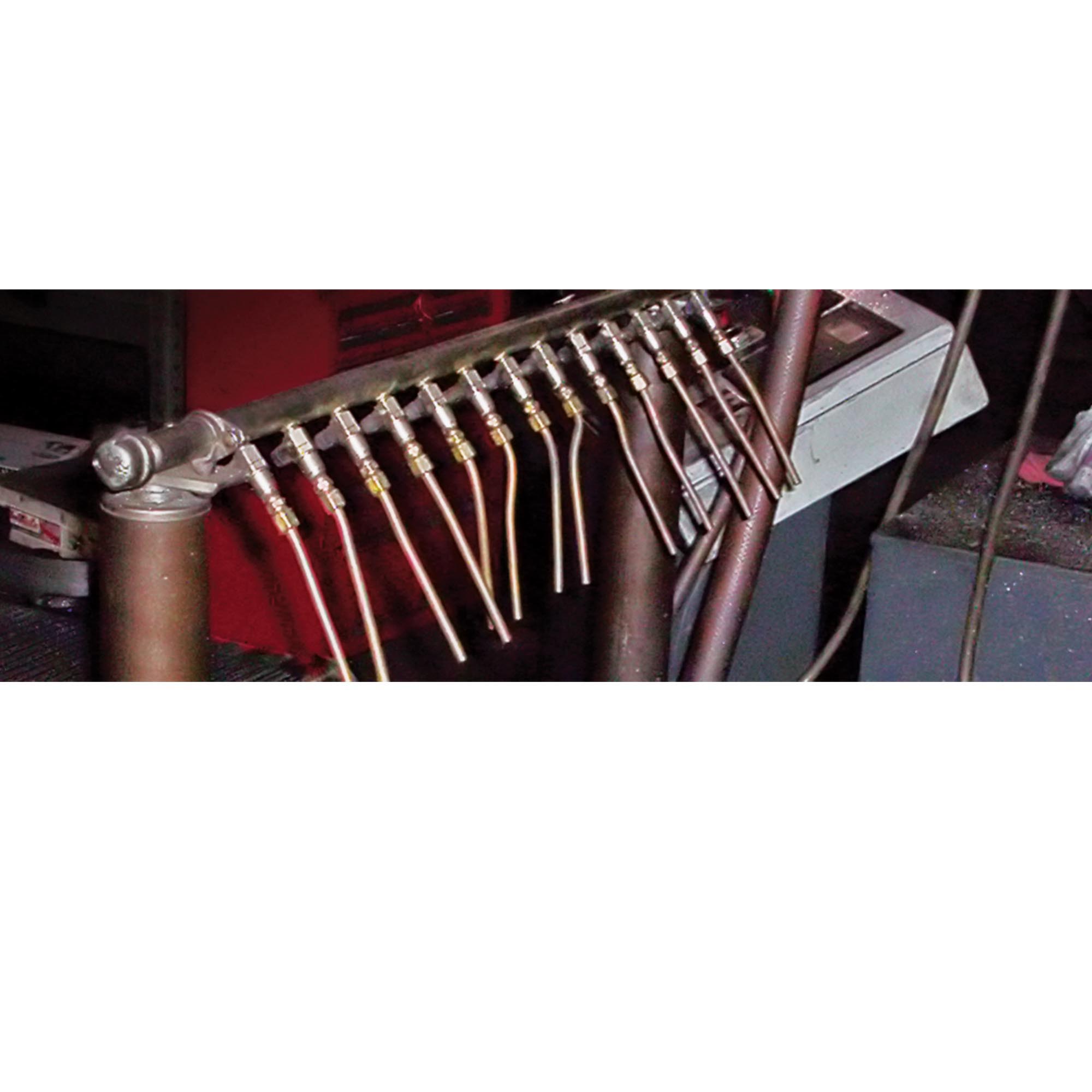

The inefficient use of compressed air for blowoff applications may create problems due to the energy costs, noise level and potential danger to personnel who are exposed to high pressure air. Open air pipes, copper tubes and drilled pipes are a few of the common abusers. They consume tremendous amounts of energy and often produce noise levels over 100 dBA.

Reduce Energy Costs

The best way to cut energy costs is through proper maintenance and use of the compressed air system. Leaks and dirty filters require maintenance on a regular basis. Energy savings can also be realized when replacing outdated compressor motors and controls with high efficiency models that often pay for themselves in a short period of time.

The most important factor to dramatically boost efficiency is proper use. Using engineered products like EXAIR's Super Air Nozzles can cut operating costs since they use only a fraction of the compressed air of typical blowoffs. In addition, all of EXAIR's Air Nozzles and Jets can be cycled on and off with an instantaneous response. EXAIR's EFC is an electronic flow control that limits compressed air use by turning on the air only when a part is present.

Reduce Noise Levels

High noise levels are a common problem for many plants. Compressed air noise often exceeds OSHA noise level exposure requirements, resulting in hearing loss to those working in close proximity. Noisy blowoffs at 80 PSIG (5.5 BAR) that produce noise levels of 100 dBA can be reduced to only 74 dBA when using a Super Air Nozzle. At that pressure, it is still possible to obtain hard-hitting force without the high noise.

Eliminate Harmful Dead End Pressures

Air can be dangerous when the outlet pressure of a hole, hose or copper tube is higher than 30 PSIG (2 BAR). In the event the opening is blocked by a hand or other body part, air may enter the bloodstream through the skin, resulting in a serious injury. All of the Air Nozzles and Jets manufactured by EXAIR have been designed for safety. All are safe to be supplied with higher pressure compressed air and meet OSHA standard 29 CFR 1910.242(b).

-

Model 6313 Air Jet Shim Set

Model 6313 Air Jet Shim Set -

Model 6313 Air Jet Shim Set

Model 6313 Air Jet Shim Set