Model 811006M 6.2 SCFM E-Vac High Vacuum Generator Kit with Straight Through Muffler (Non-Porous)

Applications

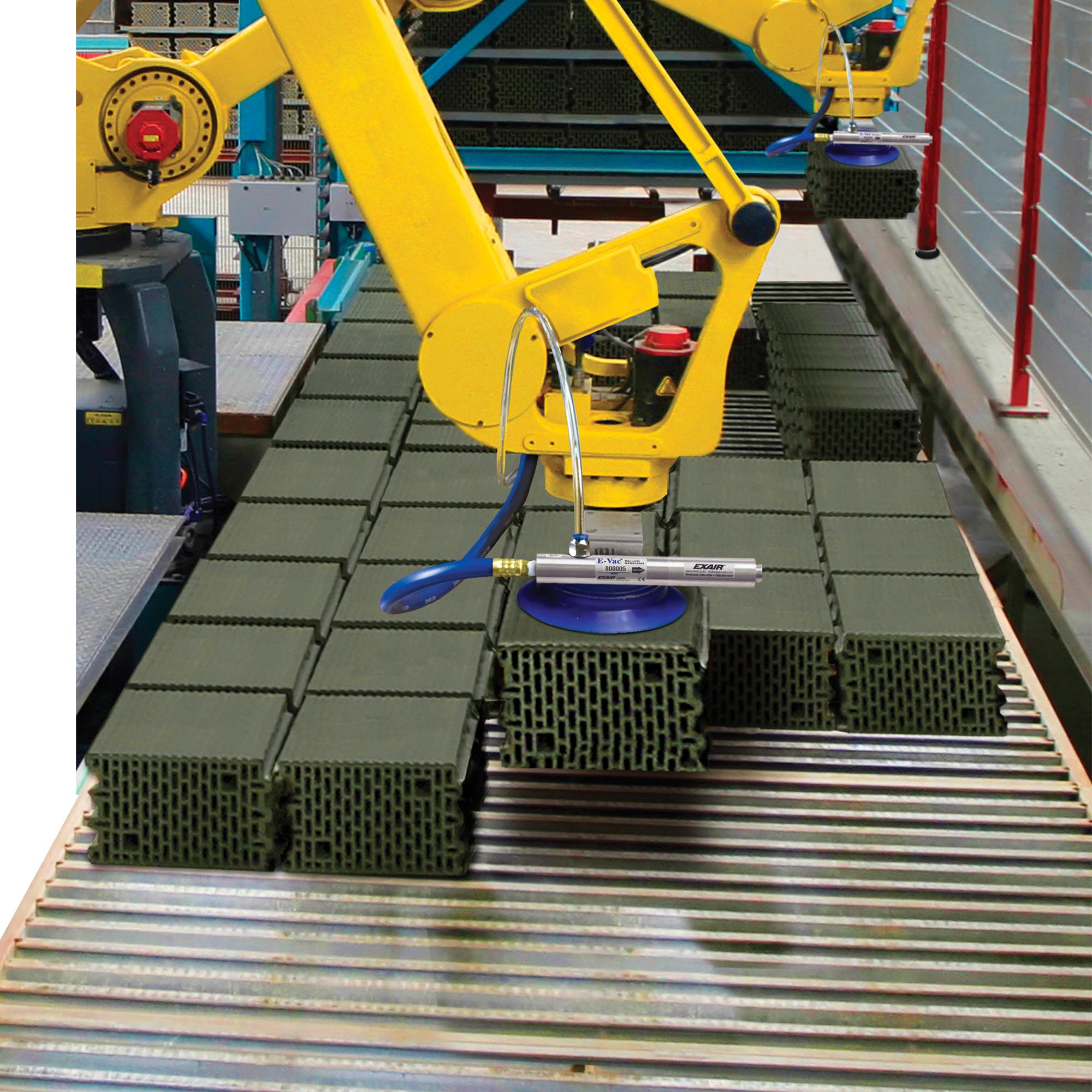

- Pick and place of parts and equipment

- Bag/package opening

- Label placement

- Vacuum forming

- Mold evacuation

- Vacuum filling

- Leak testing

- Evacuate containers

- Clamping and chucking

- Paper alignment and feed in printing equipment

- Vacuum packaging

- Surface mounting

- Vacuum press for wood veneers and laminates

- Carton forming

- Robotic tooling

- Vacuum liquids for testing

Advantages

- Compact, portable

- Single stage design eliminates fluctuations in vacuum

- Quiet

- Instantaneous vacuum

- Easy to mount at point of use

- Lightweight, rugged

- No moving parts – no maintenance

- 14 models

- Fast response – increases cycle time

- Instantaneous vacuum

- Durable 6061 aluminum construction

- Safe operation - no electricity

In-Line E-Vac Vacuum Generators

Choose the E-Vac by the SCFM (SLPM) flow that best suits the performance needed for your application (see High Vacuum Performance for Non-Porous Materials or Low Vacuum Performance for Porous Materials).

E-Vac Kits give you the ability to experiment with an assortment of Vacuum Cups. E-Vac Kits include a Muffler, an assortment of (4) pairs of Vacuum Cups (closely matched to the performance of that E-Vac), (2) straight, (2) elbow and (1) tee vacuum fittings, 10' of vacuum tubing and a mounting clip.

Deluxe Kits include the same items as the standard kit with the addition of an automatic drain filter separator for the compressed air supply and pressure regulator (with coupler).

| E-Vac High Vacuum Generators for Porous Applications | ||||||

| Model 2.3 SCFM 65 SLPM | Model 3.3 SCFM 93 SLPM | Model 6.2 SCFM 176 SLPM | Model 8.4 SCFM 238 SLPM | Model 13.2 SCFM 374 SLPM | Model 23.1 SCFM 654 SLPM | Model 30.8 SCFM 872 SLPM |

| E-Vac Only | ||||||

| 810002 | 810003 | 810006 | 810008 | 810013 | 810023 | 810031 |

| E-Vac Kit With No Muffler (Includes E-Vac, Vacuum Cups, Fittings, Tubing, Mounting Clip) | ||||||

| 811002 | 811003 | 811006 | 811008 | 811013 | 811023 | 811031 |

| E-Vac Deluxe Kit With No Muffler (Includes E-Vac, Vacuum Cups, Fittings, Tubing, Mounting Clip, Filter & Regulator) | ||||||

| 812002 | 812003 | 812006 | 812008 | 812013 | 812023 | 812031 |

| E-Vac With Standard Muffler | ||||||

| 810002H | 810003H | 810006H | 810008H | 810013H | 810023H | 810031H |

| E-Vac Kit With Standard Muffler (Includes E-Vac, Muffler, Vacuum Cups, Fittings, Tubing, Mounting Clip) | ||||||

| 811002H | 811003H | 811006H | 811008H | 811013H | 811023H | 811031H |

| E-Vac Deluxe Kit With Standard Muffler (Includes E-Vac, Muffler, Vacuum Cups, Fittings, Tubing, Mounting Clip, Filter & Regulator) | ||||||

| 812002H | 812003H | 812006H | 812008H | 812013H | 812023H | 812031H |

| E-Vac With Straight Through Muffler | ||||||

| 810002M | 810003M | 810006M | 810008M | 810013M | 810023M | 810031M |

| E-Vac Kit With Straight Through Muffler (Includes E-Vac, Muffler, Vacuum Cups, Fittings, Tubing, Mounting Clip) | ||||||

| 811002M | 811003M | 811006M | 811008M | 811013M | 811023M | 811031M |

| E-Vac Deluxe Kit With Straight Through Muffler (Includes E-Vac, Muffler, Vacuum Cups, Fittings, Tubing, Mounting Clip, Filter & Regulator) | ||||||

| 812002M | 812003M | 812006M | 812008M | 812013M | 812023M | 812031M |

Accessories

Accessories Needed To Build Your Vacuum System

EXAIR offers a variety of mufflers, tubing, check valves, and fittings that make it easy to build a vacuum system best suited to your vacuum application. In addition to these E-Vac vacuum generator accessories, there are other items that can help with the preparation and control of the compressed air.

When using E-Vac vacuum generators, it is important to use a source of clean, dry compressed air that will keep them operating at their peak performance. Automatic drain filter separators to keep the compressed air free of contaminants and moisture are recommended. Oil removal filters that remove oil particulate that is common to many compressed air systems are available. Pressure regulators, shutoff valves, compressed air hose, fittings, and solenoid valves (to electrically turn the compressed air on and off) are available as well.

Mufflers

Optional silencing mufflers are available that permit maximum exhaust of the E-Vac unit so cycle speed is not reduced. The Standard Muffler (for use with In-Line E-Vacs only) has a closed end and is suitable for applications that are free of dust and debris. The Straight Through Muffler is recommended where particulate is present since it will not accumulate debris that can erode performance. Straight Through Mufflers offer the best sound level reduction (up to 26 dBA).

Fittings and Tubing

The vacuum port of the E-Vac has an NPT thread (a vacuum cup can be threaded directly into it). For vacuum cups that are remotely located, push-in connector fittings (most have global threads for use with NPT and BSP) can be installed on the E-Vac and the vacuum cup. Polyurethane vacuum tubing is available (10', 20', 30', 40' and 50' lengths) to connect them. For best performance, the length of the tubing should be minimized to achieve the best attach and release times.

Check Valve

A vacuum check valve is available to hold the vacuum in case of compressed air loss. It is designed for high flow so it doesn’t restrict airflow or slow the vacuum operation. Maximum vacuum can still be achieved without affecting the performance. E-Vac vacuum generators that are used without a check valve will release the load if there is a significant drop in compressed air pressure or the supply of compressed air is lost.

| Standard Mufflers | |||

| Model | Description | Thread | |

| 900800 | Standard Muffler | 1/4 MNPT | |

| 900801 | Standard Muffler | 3/8 MNPT | |

| 900802 | Standard Muffler | 1/2 MNPT | |

| Straight-Through Mufflers | |||

| Model | Description | Thread | |

| 890001 | Straight-Through Muffler | 1/4 MNPS | |

| 890002 | Straight-Through Muffler | 3/8 MNPS | |

| 890003 | Straight-Through Muffler | 1/2 MNPS | |

| 890004 | Straight-Through Muffler | 3/4 MNPS | |

| 890005 | Straight-Through Muffler | 1 MNPS | |

| Check Valves | |||

| Model | Description | Thread | |

| 900804 | Check Valve | 1/4 FNPT | |

| 900805 | Check Valve | 3/8 FNPT | |

| 900806 | Check Valve | 1/2 FNPT | |

| Vacuum Gauge | |||

| Model | Description | Thread | |

| 900811 | Vacuum Gauge | 0-30" Hg | |

| Push-In Connector | |||

| Model | Description | ||

| 900773 | 1/4 Tube X 1/8 FNPT | ||

| 900774 | 1/4 Tube X 1/8 Male Global Thread | ||

| 900775 | 1/4 Tube X 1/4 Male Global Thread | ||

| 900776 | 1/4 Tube X 3/8 Male Global Thread | ||

| 900777 | 3/8 Tube X 1/8 Male Global Thread | ||

| 900778 | 3/8 Tube X 1/4 Male Global Thread | ||

| 900779 | 3/8 Tube X 3/8 Male Global Thread | ||

| 900780 | 3/8 Tube X 1/2 Male Global Thread | ||

| Push-In Swivel Elbow Connector | |||

| Model | Description | ||

| 900781 | 1/4 Tube X 1/8 Male Global Thread | ||

| 900782 | 1/4 Tube X 1/4 Male Global Thread | ||

| 900783 | 1/4 Tube X 3/8 Male Global Thread | ||

| 900784 | 3/8 Tube X 1/8 Male Global Thread | ||

| 900785 | 3/8 Tube X 1/4 Male Global Thread | ||

| 900786 | 3/8 Tube X 3/8 Male Global Thread | ||

| 900787 | 3/8 Tube X 1/2 Male Global Thread | ||

| Push-In Swivel Branch Tee Connector | |||

| Model | Description | ||

| 900788 | 1/4 Tube X 1/8 Male Global Thread | ||

| 900789 | 1/4 Tube X 1/4 Male Global Thread | ||

| 900790 | 3/8 Tube X 1/4 Male Global Thread | ||

| 900791 | 3/8 Tube X 3/8 Male Global Thread | ||

| Push-In Bulkhead Connector | |||

| Model | Description | ||

| 900792 | Female Union - 1/4 Tube X 1/4 Tube | ||

| 900793 | Female Union - 3/8 Tube X 3/8 Tube | ||

| 900809 | Female Union - 1/4 Tube X 1/4 NPT | ||

| 900810 | Female Union - 3/8 Tube X 1/4 NPT | ||

| Vacuum Tubing | |||

| Model | Description | ||

| 900795-10 | 1/4" Polyurethane Tubing - 10' (3m) | ||

| 900795-20 | 1/4" Polyurethane Tubing - 20' (6m) | ||

| 900795-30 | 1/4" Polyurethane Tubing - 30' (9m) | ||

| 900795-40 | 1/4" Polyurethane Tubing - 40' (12m) | ||

| 900795-50 | 1/4" Polyurethane Tubing - 50' (15m) | ||

| 900796-10 | 3/8" Polyurethane Tubing - 10' (3m) | ||

| 900796-20 | 3/8" Polyurethane Tubing - 20' (6m) | ||

| 900796-30 | 3/8" Polyurethane Tubing - 30' (9m) | ||

| 900796-40 | 3/8" Polyurethane Tubing - 40' (12m) | ||

| 900796-50 | 3/8" Polyurethane Tubing - 50' (15m) | ||

| Mounting Clip | |||

| Model | Description | ||

| 900798 | Mounting Clip with Strap | ||

Two Styles – Low Vacuum and High Vacuum

EXAIR manufacturers two styles of E-Vac – High Vacuum and Low Vacuum. The application will dictate which type of vacuum is most suitable.

Low vacuum units up to 21" Hg (71 kPa) are typically used for porous materials such as cardboard, and delicate materials. The low level vacuum prevents any warping, marring, dimpling or disfiguring of the surface due to excessive vacuum. This style generates more vacuum flow to overcome porosity and leakage.

High vacuum units up to 27" Hg (91 kPa) are typically used for non-porous materials such as glass, steel sheet, and plastic.

High Vacuum Generator Performance

High Vacuum Generator Performance (Non-Porous) | |||||||||||||||

| Model | Air Consumption SCFM @ 80 PSIG | Noise Level in dBA | Vacuum Flow SCFM vs. Vacuum Level “Hg | ||||||||||||

| No Muffler | Std. Muffler | Straight Through Muffler | 0 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | Max Vac | ||

| 810002 | 2.3 | 86 | 81 | 70 | 1.22 | 1.16 | 1.00 | 0.90 | 0.87 | 0.74 | 0.56 | 0.46 | 0.20 | 0.00 | 27 |

| 810003 | 3.3 | 87 | 82 | 73 | 1.73 | 1.59 | 1.48 | 1.24 | 1.09 | 1.02 | 0.78 | 0.67 | 0.49 | 0.00 | 27 |

| 810006 | 6.2 | 91 | 82 | 77 | 2.75 | 2.65 | 2.26 | 2.05 | 1.87 | 1.59 | 1.13 | 0.92 | 0.77 | 0.00 | 27 |

| 810008 | 8.4 | 97 | 90 | 78 | 4.40 | 4.10 | 3.75 | 3.15 | 2.75 | 2.39 | 1.75 | 1.27 | 0.99 | 0.00 | 27 |

| 810013 | 13.2 | 100 | 92 | 83 | 6.85 | 6.50 | 5.81 | 4.89 | 4.12 | 3.51 | 2.61 | 1.92 | 1.31 | 0.00 | 27 |

| 810023 | 23.1 | 102 | 92 | 84 | 11.95 | 11.80 | 10.45 | 9.02 | 8.10 | 6.52 | 4.54 | 3.65 | 2.67 | 0.00 | 27 |

| 810031 | 30.8 | 105 | 92 | 87 | 15.75 | 15.25 | 12.67 | 11.12 | 10.25 | 7.97 | 5.98 | 5.04 | 3.41 | 0.00 | 27 |

Max Vac for listed models is 27" Hg

High Vacuum Generator Evacuation Time (Non-Porous) | |||||||||||

| Model | Air Consumption SCFM @ 80 PSIG | Time in seconds to evacuate a 1 cubic foot container down to listed vacuum (shown in "Hg). | |||||||||

| 0 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | ||

| 810002 | 2.3 | 0.00 | 3.95 | 9.85 | 17.85 | 27.55 | 39.05 | 59.00 | 82.60 | 141.20 | 400.10 |

| 810003 | 3.3 | 0.00 | 2.75 | 6.55 | 12.35 | 19.55 | 29.15 | 42.55 | 61.75 | 94.25 | 231.85 |

| 810006 | 6.2 | 0.00 | 1.95 | 4.50 | 7.95 | 12.35 | 18.55 | 28.50 | 43.30 | 65.75 | 165.45 |

| 810008 | 8.4 | 0.00 | 1.05 | 2.45 | 4.70 | 7.35 | 10.85 | 16.25 | 24.85 | 38.45 | 90.15 |

| 810013 | 13.2 | 0.00 | 0.75 | 1.60 | 2.95 | 4.50 | 6.55 | 10.15 | 16.10 | 27.30 | 71.45 |

| 810023 | 23.1 | 0.00 | 0.50 | 1.00 | 1.70 | 2.60 | 3.80 | 5.55 | 8.25 | 13.30 | 51.30 |

| 810031 | 30.8 | 0.00 | 0.40 | 0.90 | 1.60 | 2.35 | 3.40 | 5.05 | 7.45 | 11.55 | 45.70 |

High Vacuum Generator Performance (Non-Porous) | ||||||||||||||

| Model | Air Consumpt. SLPM @ 5.5 BAR | Noise Level in dBA | Vacuum Flow SCFM vs. Vacuum Level “Hg | |||||||||||

| No Muffler | Std. Muffler | Straight Through Muffler | 0 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | ||

| 810002 | 65.1 | 86 | 81 | 70 | 34.5 | 33.0 | 28.3 | 25.5 | 24.6 | 21.0 | 16.0 | 13.0 | 5.7 | 0.00 |

| 810003 | 93.4 | 87 | 82 | 73 | 49.0 | 45.0 | 41.9 | 35.1 | 30.9 | 28.9 | 22.1 | 19.0 | 13.9 | 0.00 |

| 810006 | 175.6 | 91 | 82 | 77 | 78.0 | 75.0 | 64.0 | 58.0 | 53.0 | 45.0 | 32.0 | 26.0 | 21.7 | 0.00 |

| 810008 | 237.9 | 97 | 90 | 78 | 124.6 | 116.1 | 106.2 | 89.2 | 77.9 | 67.7 | 49.6 | 36.0 | 28.0 | 0.00 |

| 810013 | 373.8 | 100 | 92 | 83 | 194.0 | 184.1 | 164.5 | 138.5 | 116.7 | 99.4 | 73.9 | 54.4 | 37.1 | 0.00 |

| 810023 | 654.1 | 102 | 92 | 84 | 338.4 | 334.1 | 295.9 | 255.4 | 229.4 | 184.6 | 128.6 | 103.4 | 75.6 | 0.00 |

| 810031 | 872.1 | 105 | 92 | 87 | 446.0 | 431.8 | 358.8 | 314.9 | 290.2 | 225.7 | 169.3 | 142.7 | 96.6 | 0.00 |

Max Vac for listed models is 91 kPa

High Vacuum Generator Evacuation Time (Non-Porous) | |||||||||||

| Model | Air Consumpt. SLPM @ 5.5 BAR | Time in seconds to evacuate a 0.3 cubic meter container down to listed vacuum (shown in kPa). | |||||||||

| 0 | 3 | 6 | 9 | 12 | 15 | 18 | 21 | 24 | 27 | ||

| 810002 | 65.1 | 0.00 | 3.95 | 9.85 | 17.85 | 27.55 | 39.05 | 59.00 | 82.60 | 141.20 | 400.10 |

| 810003 | 93.4 | 0.00 | 2.75 | 6.55 | 12.35 | 19.55 | 29.15 | 42.55 | 61.75 | 94.25 | 231.82 |

| 810006 | 175.6 | 0.00 | 1.95 | 4.50 | 7.95 | 12.35 | 18.55 | 28.50 | 43.30 | 65.75 | 165.45 |

| 810008 | 237.9 | 0.00 | 1.05 | 2.45 | 4.70 | 7.35 | 10.85 | 16.25 | 24.85 | 38.45 | 90.15 |

| 810013 | 373.8 | 0.00 | 0.75 | 1.60 | 2.95 | 4.50 | 6.55 | 10.15 | 16.10 | 27.30 | 71.45 |

| 810023 | 654.1 | 0.00 | 0.50 | 1.00 | 1.70 | 2.60 | 3.80 | 5.55 | 8.25 | 13.30 | 51.30 |

| 810031 | 872.1 | 0.00 | 0.40 | 0.90 | 1.60 | 2.35 | 3.40 | 5.05 | 7.45 | 11.55 | 45.70 |

In-Line E-Vac Dimensions |

||||||||||||

|

||||||||||||

Vacuum Generator Dimensions |

||||||||||||

| Model | Air Inlet A | Vacuum Inlet B | C | D | E | F | G | H | J | K | ||

| 800001 800002 800003 810002 810003 810006 | 1/8 NPT | 1/8 NPT |

in | N/A | N/A | 3.00 | 0.88 | 0.75 | 1/4 NPT | N/A | N/A | |

| mm | N/A | N/A | 76 | 22 | 19 | N/A | N/A | |||||

| 800001H 800002H 800003H 810002H 810003H 810006H | 1/8 NPT | 1/8 NPT |

in | N/A | 5.00 | 3.00 | 0.88 | 0.75 | 1/4 NPT | N/A | 0.81 | |

| mm | N/A | 127 | 76 | 22 | 19 | N/A | 21 | |||||

| 800001M 800002M 800003M 810002M 810003M 810006M | 1/8 NPT | 1/8 NPT |

in | 5.25 | N/A | 3.00 | 0.88 | 0.75 | 1/4 NPT | 1/4 NPS | 0.75 | |

| mm | 1.33 | N/A | 76 | 22 | 19 | 1/4 NPS | 19 | |||||

| 800005 800008 810008 810013 | 1/4 NPT | 3/8 NPT |

in | N/A | N/A | 4.50 | 1.50 | 1.00 | 3/8 NPT | N/A | N/A | |

| mm | N/A | N/A | 114 | 38 | 25 | N/A | N/A | |||||

| 800005H 800008H 810008H 810013H | 1/4 NPT | 3/8 NPT |

in | N/A | 7.50 | 4.50 | 1.50 | 1.00 | 3/8 NPT | N/A | 1.25 | |

| mm | N/A | 191 | 114 | 38 | 25 | N/A | 32 | |||||

| 800005M 800008M 810008M 810013M | 1/4 NPT | 3/8 NPT |

in | 7.75 | N/A | 4.50 | 1.50 | 1.00 | 3/8 NPT | 3/8 NPS | 1.00 | |

| mm | 197 | N/A | 114 | 38 | 25 | 3/8 NPS | 25 | |||||

| 800013 800017 810023 810031 | 1/2 NPT | 1/2 NPT |

in | N/A | N/A | 6.00 | 1.88 | 1.25 | 1/2 NPT | N/A | N/A | |

| mm | N/A | N/A | 152 | 48 | 32 | N/A | N/A | |||||

| 800013H 800017H 810023H 810031H | 1/2 NPT | 1/2 NPT |

in | N/A | 9.00 | 6.00 | 1.88 | 1.25 | 1/2 NPT | N/A | 1.25 | |

| mm | N/A | 229 | 152 | 48 | 32 | N/A | 32 | |||||

| 800013M 800017M 810023M 810031M | 1/2 NPT | 1/2 NPT |

in | 10.25 | N/A | 6.00 | 1.88 | 1.25 | 1/2 NPT | 1/2 NPS | 1.25 | |

| mm | 260 | N/A | 152 | 48 | 32 | 1/2 NPS | 32 | |||||

How The In-Line E-Vac Works | |

| |

Compressed air flows through the inlet (1), then through a single directed nozzle (2). As the airstream exhausts, it expands and increases in velocity prior to passing through the venturi (3). A vacuum inlet tangential to the primary airflow (4) is located at the suction point between the orifice and the venturi. The airflow that is drawn through the vacuum inlet mixes with the primary airstream, then exhausts on the opposite end (5). | |

In-Line E-Vac Standards and Certifications

EXAIR In-Line E-Vacs comply with OSHA's Safety Requirements, the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC). All sound level measurements are taken at 3 feet away.

Look for this symbol to designate conflict mineral free products throughout our website. EXAIR supports Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act and we are committed to compliance with the conflict minerals rule in order to curb the illicit trade of tin, tantalum, tungsten and gold in the DRC region. EXAIR is using the CMRT 3.02 template to document our supply chain and commitment to conflict free products.

How to Build An E-Vac System |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Here is an example using the steps outlined above: If it is porous, like wood, and positioned vertically:

If it is non-porous, like glass, and positioned horizontally:

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Increased Energy and Vacuum Efficiency

Energy and vacuum efficiency are not limited to the Adjustable E-Vac vacuum generators. All E-Vac styles and models can offer significant improvements when looking to reduce the amount of compressed air used for a specific vacuum application. Once the appropriate amount of vacuum and flow for the application are determined, it is important to select the appropriate model that will deliver the best performance while using the least amount of compressed air that it takes to do the job.

Many companies have a centralized vacuum system where the vacuum is generated at a location that is far away from the point of use. The long runs of piping through the plant produce line loss and it is often difficult to obtain that perfect balance of vacuum and flow required for an application. The compact In-line E-Vac vacuum generators eliminate this problem since they can be mounted at the point where the vacuum source is needed. EXAIR’s Application Engineers can help you to select the E-Vac vacuum generator and vacuum cups that provide the right amount of lifting capability while minimizing the amount of compressed air usage.

Other Applications for the E-Vac

E-Vacs are used in many other “non-lifting” applications. They are commonly used for vessel evacuation, clamping, chucking, and other work holding applications. Many types of automated equipment use vacuum to evacuate, grip, hold, align and insert parts. These vacuums can be used for surface mounting, vacuum packaging, bag opening, label placement, carton forming and container evacuation.

Another popular application is using the E-Vac for liquid sampling. This process can easily be accomplished using an E-Vac vacuum generator attached to a liquid holding tube. When the tube is dipped into the vat, tank or container, the compressed air is turned on so it draws a specific volume of liquid up into the tube. When the compressed air is turned off , the liquid flows from the tube and can be dispensed into a container or machine to be analyzed.

Choosing An E-Vac

E-Vac® Vacuum Generators Are Easy To Use

The construction of the E-Vac is aluminum. The vacuum inlet can be easily connected to existing tubing, piping and hose. Durable vinyl vacuum cups for pick and place applications are available. Optional silencing mufflers are available that permit maximum exhaust of the E-Vac unit so cycle speed is not reduced.

Choosing The Appropriate E-Vac Vacuum Generator

EXAIR’s E-Vac is available in 2 styles that include the In-Line E-Vac and Adjustable E-Vac. Each design has been engineered for use in a variety of applications. These single stage, all aluminum units provide consistent, steady vacuum, unlike mechanical vacuum pumps. Dust and small particulates easily pass through the vacuum generator and they have no moving parts, making them maintenance free.

In-Line E-Vac Vacuum Generator

This series of single stage, cylindrical vacuum generators are compact and easy to mount at the point of use. The In-Line E-Vac can be held in place by threading them directly onto a compressed air line or with use of a mounting clip. Each In-Line vacuum model has a specific level of vacuum and flow. This style can easily pass dust or small particulates. There are 7 models suitable for use when lifting porous materials (like cardboard). The “porous” models have vacuum levels up to 21"Hg (71kPa) with vacuum flows up to 18.5 SCFM (524 SLPM). There are 7 models for use with non-porous materials (like glass) that have vacuum levels up to 27" Hg (91 kPa) with vacuum flows up to 15.8 SCFM (447 SLPM).

Adjustable E-Vac Vacuum Generator

This series of Adjustable E-Vac single stage vacuum generators permit easy adjustment by simply loosening the locknut and turning the exhaust to increase or decrease the level of vacuum and vacuum flow. These are ideal for use with porous and non-porous materials where the load can vary. Vacuum flow is easily increased when the vacuum is being used on a porous surface. This style passes dust and larger size particulates so there is no loss in vacuum, making it the best choice when working with dirty, dusty materials (such as concrete mix, plaster, etc.) There are 4 models with adjustable vacuum up to 25"Hg (85kPa) and vacuum flow up to 81 SCFM (2,294 SLPM).

-

Model 811006M 6.2 SCFM E-Vac High Vacuum Generator Kit with Straight Through Muffler (Non-Porous)

Model 811006M 6.2 SCFM E-Vac High Vacuum Generator Kit with Straight Through Muffler (Non-Porous)