Model AF6020SS 231 GPH 1/2 FNPT No Drip Internal Mix Flat Fan Atomizing Nozzle

Applications

- Washing

- Rinsing

- Coating

- Cooling

- Quenching

- Wetting (moistening)

- Humidification

- Dust Control

Advantages

- Fully adjustable

- Maximizes liquid dispersion

- Minimizes liquid consumption

- All stainless steel construction

- Compact

- Versatile

- Interchangeable liquid and air caps

- Minimizes air consumption

- Fine atomization

Atomizing Nozzle Materials

Type 303 Stainless Steel - All of EXAIR's Atomizing Nozzles are constructed with Type 303 stainless steel, which can resist high temperatures and corrosive environments. They are designed for environments with a maximum operating temperature of 800°F (426°C).

Accessories

Mounting Brackets - available for 1/8 FNPT, 1/4 FNPT and 1/2 FNPT models. Provides a secure mount for EXAIR's Atomizing Nozzles. Constructed of Type 301 stainless steel.

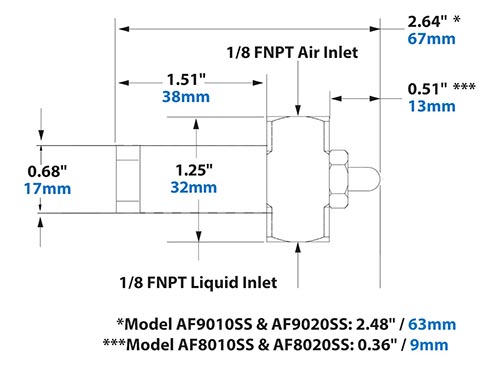

Dimensions & PerformanceNo Drip Internal Mix Flat Fan Pattern Atomizing Nozzles(1/8 FNPT Models) |

||||||||||||||||||

|

||||||||||||||||||

Liquid Pressure |

AF9010SS |

AF9020SS |

AF9030SS |

AF9040SS |

||||||||||||||

| 10 PSI / 0.7 BAR | Air Press | PSI | 10 | 14 | 22 | -- | 18 | 22 | 26 | -- | 16 | 18 | 20 | 24 | 12 | 14 | 20 | -- |

| BAR | 0.7 | 1.0 | 1.5 | -- | 1.2 | 1.5 | 1.8 | -- | 1.1 | 1.2 | 1.4 | 1.7 | 0.8 | 1.0 | 1.4 | -- | ||

| Liquid Flow | GPH | 1.60 | 1.43 | 0.93 | -- | 1.53 | 1.40 | 1.00 | -- | 7.83 | 7.83 | 7.50 | 7.43 | 11.2 | 10.3 | 8.33 | -- | |

| LPH | 6.1 | 5.4 | 3.5 | -- | 5.8 | 5.3 | 3.8 | -- | 29.6 | 29.6 | 28.4 | 28.1 | 42.3 | 39.1 | 31.5 | -- | ||

| Air Flow | SCFM | 0.71 | 0.76 | 1.03 | -- | 1.04 | 1.17 | 1.29 | -- | 1.42 | 1.56 | 1.69 | 1.82 | 1.08 | 1.19 | 1.51 | -- | |

| SLPM | 20.0 | 21.6 | 29.1 | -- | 29.5 | 33.2 | 36.5 | -- | 40.3 | 44.1 | 47.9 | 51.6 | 30.5 | 33.6 | 42.7 | -- | ||

| 20 PSI / 1.4 BAR | Air Press | PSI | 18 | 26 | 40 | -- | 30 | 36 | 40 | 44 | 28 | 30 | 32 | 36 | 22 | 26 | 34 | 38 |

| BAR | 1.2 | 1.8 | 2.8 | -- | 2.1 | 2.5 | 2.8 | 3.0 | 1.9 | 2.1 | 2.2 | 2.5 | 1.5 | 1.8 | 2.3 | 2.6 | ||

| Liquid Flow | GPH | 2.13 | 1.87 | 1.40 | -- | 2.30 | 1.90 | 1.63 | 0.85 | 10.8 | 10.7 | 10.3 | 10.3 | 14.8 | 14.3 | 12.3 | 11.7 | |

| LPH | 8.1 | 7.1 | 5.3 | -- | 8.7 | 7.2 | 6.2 | 3.2 | 41.0 | 40.4 | 39.1 | 39.1 | 56.2 | 54.3 | 46.7 | 44.2 | ||

| Air Flow | SCFM | 1.11 | 1.44 | 1.94 | -- | 2.30 | 1.90 | 1.63 | 0.85 | 2.00 | 2.14 | 2.24 | 2.49 | 1.56 | 1.72 | 2.15 | 2.43 | |

| SLPM | 31.5 | 40.7 | 55.0 | -- | 65.1 | 53.8 | 46.2 | 24.1 | 56.7 | 60.4 | 63.5 | 70.5 | 44.1 | 48.7 | 60.9 | 68.7 | ||

| 30 PSI / 2.1 BAR | Air Press | PSI | 28 | 36 | 55 | -- | 42 | 46 | 50 | -- | 38 | 40 | 42 | 46 | 34 | 38 | 48 | 50 |

| BAR | 1.9 | 2.5 | 3.8 | -- | 2.9 | 3.2 | 3.4 | -- | 2.6 | 2.8 | 2.9 | 3.2 | 2.3 | 2.6 | 3.3 | 3.4 | ||

| Liquid Flow | GPH | 2.63 | 2.20 | 1.63 | -- | 2.87 | 2.60 | 2.20 | -- | 13.0 | 13.0 | 12.5 | 12.5 | 17.8 | 17.3 | 15.3 | 14.8 | |

| LPH | 10.0 | 8.3 | 6.2 | -- | 10.9 | 9.8 | 8.3 | -- | 49.2 | 49.2 | 47.3 | 47.3 | 67.5 | 65.6 | 58.0 | 56.2 | ||

| Air Flow | SCFM | 1.53 | 1.94 | 2.67 | -- | 2.05 | 2.20 | 2.38 | -- | 2.54 | 2.67 | 2.80 | 2.94 | 2.15 | 2.28 | 2.75 | 2.88 | |

| SLPM | 43.4 | 54.8 | 75.4 | -- | 57.9 | 62.2 | 67.5 | -- | 71.8 | 75.6 | 79.3 | 83.1 | 60.9 | 64.5 | 77.9 | 81.6 | ||

| 40 PSI / 2.8 BAR | Air Press | PSI | 38 | 46 | 70 | -- | 55 | 65 | -- | -- | 46 | 50 | 52 | 56 | 46 | 50 | 60 | 70 |

| BAR | 2.6 | 3.2 | 4.8 | -- | 3.8 | 4.5 | -- | -- | 3.2 | 3.4 | 3.6 | 3.9 | 3.2 | 3.4 | 4.1 | 4.8 | ||

| Liquid Flow | GPH | 2.87 | 2.57 | 2.07 | -- | 3.53 | 2.67 | -- | -- | 14.7 | 14.2 | 14.2 | 13.7 | 20.3 | 19.7 | 18.3 | 17.0 | |

| LPH | 10.9 | 9.7 | 7.8 | -- | 13.4 | 10.1 | -- | -- | 55.5 | 53.6 | 53.6 | 51.7 | 77.0 | 74.4 | 69.4 | 64.4 | ||

| Air Flow | SCFM | 1.95 | 2.28 | 3.17 | -- | 2.56 | 2.98 | -- | -- | 2.94 | 3.20 | 3.28 | 3.47 | 2.71 | 2.92 | 3.36 | 3.91 | |

| SLPM | 55.1 | 64.7 | 89.8 | -- | 72.5 | 84.4 | -- | -- | 83.1 | 90.7 | 92.9 | 98.2 | 76.7 | 82.8 | 95.0 | 111 | ||

| 60 PSI / 4.1 BAR | Air Press | PSI | 55 | 75 | 100 | -- | 75 | 85 | -- | -- | 65 | 70 | 75 | 85 | 65 | 75 | 90 | 100 |

| BAR | 3.8 | 5.2 | 6.9 | -- | 5.2 | 5.9 | -- | -- | 4.5 | 4.8 | 5.2 | 5.9 | 4.5 | 5.2 | 6.2 | 6.9 | ||

| Liquid Flow | GPH | 3.47 | 2.93 | 2.37 | -- | 4.27 | 3.67 | -- | -- | 17.0 | 16.7 | 16.5 | 16.2 | 28.0 | 26.3 | 23.3 | 22.7 | |

| LPH | 13.1 | 11.1 | 9.0 | -- | 16.2 | 13.9 | -- | -- | 64.4 | 63.1 | 62.5 | 61.2 | 106 | 99.7 | 88.3 | 85.8 | ||

| Air Flow | SCFM | 2.57 | 3.42 | 4.33 | -- | 3.25 | 3.69 | -- | -- | 4.00 | 4.14 | 4.54 | 4.76 | 3.61 | 4.14 | 4.80 | 5.33 | |

| SLPM | 72.7 | 96.9 | 123 | -- | 91.9 | 105 | -- | -- | 113 | 117 | 128 | 135 | 102 | 117 | 136 | 151 | ||

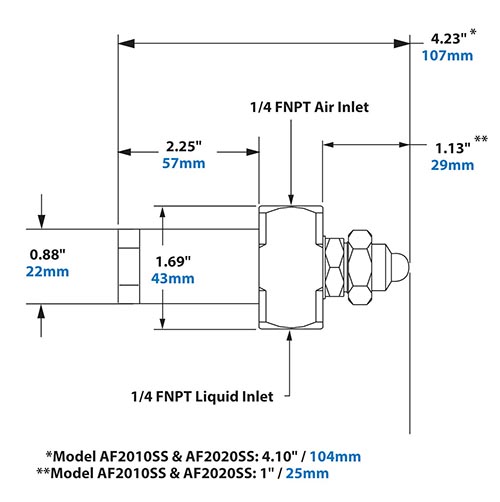

Dimensions & PerformanceNo Drip Internal Mix Flat Fan Pattern Atomizing Nozzles(1/4 FNPT Models) |

||||||||||||||||||||||

|

||||||||||||||||||||||

Liquid Pressure |

AF2010SS |

AF2020SS |

AF2030SS |

AF2040SS |

AF2050SS |

|||||||||||||||||

| 10 PSI / 0.7 BAR | Air Press | PSI | 10 | 14 | 18 | 22 | 12 | 16 | 18 | 20 | 16 | 20 | 24 | 28 | 12 | 16 | 18 | 22 | 14 | 16 | -- | -- |

| BAR | 0.7 | 1.0 | 1.2 | 1.5 | 0.8 | 1.1 | 1.2 | 1.4 | 1.1 | 1.4 | 1.7 | 1.9 | 0.8 | 1.1 | 1.2 | 1.5 | 1.0 | 1.1 | -- | -- | ||

| Liquid Flow | GPH | 1.6 | 1.4 | 1.1 | 0.8 | 2.4 | 1.8 | 1.5 | 1.3 | 4.5 | 3.3 | 2.4 | 1.5 | 8.1 | 5.9 | 5.0 | 3.3 | 8.8 | 5.3 | -- | -- | |

| LPH | 6.1 | 5.3 | 4.2 | 3.0 | 9.1 | 6.8 | 5.7 | 4.9 | 17.0 | 12.5 | 9.1 | 5.7 | 30.7 | 22.3 | 18.9 | 12.5 | 33.3 | 20.1 | -- | -- | ||

| Air Flow | SCFM | 0.7 | 0.9 | 1.1 | 1.3 | 0.7 | 0.9 | 1.0 | 1.1 | 2.0 | 2.4 | 2.7 | 3.1 | 1.4 | 1.8 | 2.0 | 2.4 | 3.0 | 3.7 | -- | -- | |

| SLPM | 20 | 25 | 31 | 37 | 20 | 25 | 28 | 31 | 57 | 68 | 76 | 88 | 40 | 21 | 57 | 68 | 85 | 105 | -- | -- | ||

| 20 PSI / 1.4 BAR | Air Press | PSI | 18 | 26 | 34 | 40 | 20 | 28 | 32 | 36 | 28 | 32 | 34 | 36 | 22 | 30 | 34 | 38 | 26 | 28 | -- | -- |

| BAR | 1.2 | 1.8 | 2.3 | 2.8 | 1.4 | 1.9 | 2.2 | 2.5 | 1.9 | 2.2 | 2.3 | 2.5 | 1.5 | 2.1 | 2.3 | 2.6 | 1.8 | 1.9 | -- | -- | ||

| Liquid Flow | GPH | 2.1 | 1.7 | 1.2 | 0.8 | 3.4 | 2.4 | 1.8 | 1.4 | 6.0 | 5.0 | 4.5 | 3.9 | 12.0 | 7.1 | 5.6 | 4.1 | 11.5 | 7.8 | -- | -- | |

| LPH | 7.9 | 6.4 | 4.5 | 3.0 | 12.9 | 9.1 | 6.8 | 5.3 | 22.7 | 18.9 | 17.0 | 14.8 | 45.4 | 26.9 | 21.2 | 15.5 | 43.5 | 29.5 | -- | -- | ||

| Air Flow | SCFM | 1.0 | 1.3 | 1.7 | 1.9 | 0.9 | 1.2 | 1.5 | 1.7 | 2.8 | 3.1 | 3.3 | 3.5 | 1.9 | 2.7 | 3.1 | 3.5 | 4.3 | 4.9 | -- | -- | |

| SLPM | 28 | 37 | 48 | 54 | 25 | 34 | 42 | 48 | 79 | 88 | 93 | 99 | 54 | 76 | 88 | 99 | 122 | 139 | -- | -- | ||

| 30 PSI / 2.1 BAR | Air Press | PSI | 28 | 40 | 48 | 55 | 30 | 38 | 46 | 50 | 38 | 42 | 46 | 48 | 34 | 42 | 48 | 52 | 34 | 36 | 40 | 42 |

| BAR | 1.9 | 2.8 | 3.3 | 3.8 | 2.1 | 2.6 | 3.2 | 3.4 | 2.6 | 2.9 | 3.2 | 3.3 | 2.3 | 2.9 | 3.3 | 3.6 | 2.3 | 2.5 | 2.8 | 2.9 | ||

| Liquid Flow | GPH | 2.4 | 1.8 | 1.4 | 1.0 | 3.9 | 2.9 | 2.0 | 1.6 | 7.0 | 6.4 | 5.5 | 5.1 | 13.1 | 8.9 | 6.3 | 5.0 | 20.8 | 17.0 | 9.0 | 6.3 | |

| LPH | 9.1 | 6.8 | 5.3 | 3.8 | 14.8 | 11.0 | 7.6 | 6.1 | 26.5 | 24.2 | 20.8 | 19.3 | 49.6 | 33.7 | 23.8 | 18.9 | 78.7 | 64.3 | 34.1 | 23.8 | ||

| Air Flow | SCFM | 1.4 | 1.8 | 2.1 | 2.4 | 1.2 | 1.5 | 1.9 | 2.1 | 3.5 | 3.8 | 4.1 | 4.4 | 2.7 | 3.4 | 4.1 | 4.5 | 4.6 | 4.9 | 6.1 | 7.0 | |

| SLPM | 40 | 51 | 59 | 68 | 34 | 42 | 54 | 59 | 99 | 108 | 116 | 125 | 76 | 96 | 116 | 127 | 130 | 139 | 173 | 198 | ||

| 40 PSI / 2.8 BAR | Air Press | PSI | 38 | 50 | 60 | 70 | 38 | 50 | 60 | 70 | 46 | 52 | 58 | 60 | 46 | 54 | 60 | 70 | 42 | 46 | 50 | 54 |

| BAR | 2.6 | 3.4 | 4.1 | 4.8 | 2.6 | 3.4 | 4.1 | 4.8 | 3.2 | 3.6 | 4.0 | 4.1 | 3.2 | 3.7 | 4.1 | 4.8 | 2.9 | 3.2 | 3.4 | 3.7 | ||

| Liquid Flow | GPH | 2.6 | 2.0 | 1.6 | 1.2 | 4.6 | 3.2 | 2.2 | 1.4 | 8.5 | 7.5 | 6.3 | 6.0 | 14.3 | 10.3 | 7.9 | 4.6 | 30.0 | 20.5 | 13.5 | 7.5 | |

| LPH | 9.8 | 7.6 | 6.1 | 4.5 | 17.4 | 12.1 | 8.3 | 5.3 | 32.2 | 28.4 | 23.8 | 22.7 | 54.1 | 39.0 | 29.9 | 17.4 | 114 | 77.6 | 51.1 | 28.4 | ||

| Air Flow | SCFM | 1.7 | 2.1 | 2.5 | 3.0 | 1.4 | 1.9 | 2.3 | 2.8 | 4.0 | 4.5 | 4.9 | 5.2 | 3.4 | 4.1 | 4.8 | 5.8 | 4.8 | 6.1 | 7.3 | 8.4 | |

| SLPM | 48 | 59 | 71 | 85 | 40 | 54 | 65 | 79 | 113 | 127 | 139 | 147 | 96 | 116 | 136 | 164 | 136 | 173 | 207 | 238 | ||

| 60 PSI / 4.1 BAR | Air Press | PSI | 55 | 75 | 90 | 100 | 65 | 75 | 85 | 95 | 65 | 70 | 80 | 90 | 65 | 80 | 90 | 100 | 58 | 65 | 70 | 80 |

| BAR | 3.8 | 5.2 | 6.2 | 6.9 | 4.5 | 5.2 | 5.9 | 6.6 | 4.5 | 4.8 | 5.5 | 6.2 | 4.5 | 5.5 | 6.2 | 6.9 | 4.0 | 4.5 | 4.8 | 5.5 | ||

| Liquid Flow | GPH | 3.2 | 2.3 | 1.6 | 1.3 | 4.7 | 3.7 | 2.8 | 2.1 | 11.0 | 10.0 | 8.0 | 6.4 | 18.3 | 11.9 | 8.5 | 6.0 | 42.0 | 30.0 | 21.0 | 8.5 | |

| LPH | 12.1 | 8.7 | 6.1 | 4.9 | 17.8 | 14.0 | 10.6 | 7.9 | 41.6 | 37.9 | 30.3 | 24.2 | 69.3 | 45.0 | 32.2 | 22.7 | 159 | 114 | 79.5 | 32.2 | ||

| Air Flow | SCFM | 2.2 | 3.0 | 3.6 | 4.1 | 2.2 | 2.6 | 3.0 | 3.6 | 5.3 | 5.7 | 6.4 | 7.2 | 4.5 | 5.9 | 6.8 | 7.9 | 5.5 | 6.8 | 8.7 | 11.2 | |

| SLPM | 62 | 85 | 102 | 116 | 62 | 74 | 85 | 102 | 150 | 161 | 181 | 204 | 127 | 167 | 193 | 224 | 156 | 193 | 246 | 317 | ||

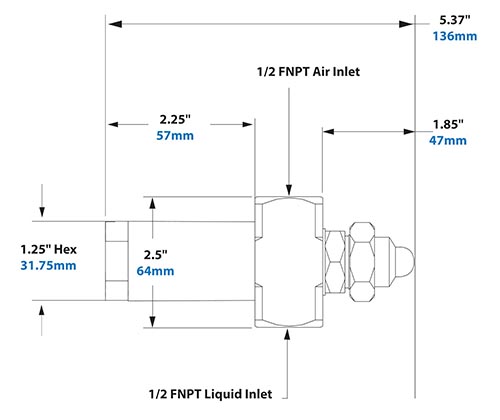

Dimensions & PerformanceNo Drip Internal Mix Flat Fan Pattern Atomizing Nozzles(1/2 FNPT Models) |

||||||||||

|

||||||||||

Liquid Pressure |

AF6010SS |

AF6020SS |

||||||||

| 5 PSI / 0.3 BAR | Air Pressure | PSI | -- | -- | -- | -- | 10 | 12 | -- | -- |

| BAR | -- | -- | -- | -- | 0.69 | 0.83 | -- | -- | ||

| Liquid Flow | GPH | -- | -- | -- | -- | 18 | 6 | -- | -- | |

| LPH | -- | -- | -- | -- | 68 | 23 | -- | -- | ||

| Air Flow | SCFM | -- | -- | -- | -- | 18.0 | 6.0 | -- | -- | |

| SLPM | -- | -- | -- | -- | 510 | 170 | -- | -- | ||

| 15 PSI / 1.0 BAR | Air Pressure | PSI | 28 | 30 | 34 | 36 | 18 | 20 | 22 | 24 |

| BAR | 1.9 | 2.1 | 2.3 | 2.5 | 1.2 | 1.4 | 1.5 | 1.7 | ||

| Liquid Flow | GPH | 33.6 | 25.2 | 12.6 | 11.5 | 87.6 | 62.4 | 45.6 | 30.6 | |

| LPH | 127 | 95 | 48 | 44 | 332 | 236 | 173 | 116 | ||

| Air Flow | SCFM | 23.4 | 25.3 | 28.7 | 31.2 | 15.6 | 18.4 | 20.6 | 23.3 | |

| SLPM | 663 | 716 | 813 | 884 | 442 | 521 | 583 | 660 | ||

| 25 PSI / 1.7 BAR | Air Pressure | PSI | 44 | 48 | 50 | 60 | 26 | 30 | 36 | 40 |

| BAR | 3.0 | 3.3 | 3.4 | 4.1 | 1.8 | 2.1 | 2.5 | 2.8 | ||

| Liquid Flow | GPH | 38.4 | 35.8 | 18 | 3.5 | 150 | 99 | 50.4 | 26.4 | |

| LPH | 145 | 136 | 68 | 13 | 568 | 375 | 191 | 100 | ||

| Air Flow | SCFM | 32.4 | 36.2 | 38.0 | 46.0 | 17.9 | 22.3 | 29.9 | 35.2 | |

| SLPM | 918 | 1025 | 1076 | 1303 | 507 | 632 | 847 | 997 | ||

| 35 PSI / 2.4 BAR | Air Pressure | PSI | 58 | 62 | 65 | 70 | 36 | 40 | 46 | 52 |

| BAR | 4.0 | 4.3 | 4.5 | 4.8 | 2.5 | 2.8 | 3.2 | 3.6 | ||

| Liquid Flow | GPH | 46.2 | 34.8 | 25.2 | 16.2 | 177 | 132 | 76.8 | 38.4 | |

| LPH | 175 | 132 | 95 | 61 | 670 | 500 | 291 | 145 | ||

| Air Flow | SCFM | 40.3 | 43.5 | 46.0 | 49.7 | 22.3 | 26.6 | 34.4 | 41.5 | |

| SLPM | 1141 | 1232 | 1303 | 1408 | 632 | 753 | 974 | 1175 | ||

| 55 PSI / 3.8 BAR | Air Pressure | PSI | -- | -- | -- | -- | 54 | 60 | 68 | 76 |

| BAR | -- | -- | -- | -- | 3.7 | 4.1 | 4.7 | 5.2 | ||

| Liquid Flow | GPH | -- | -- | -- | -- | 231 | 186 | 108 | 66 | |

| LPH | -- | -- | -- | -- | 874 | 704 | 409 | 25 | ||

| Air Flow | SCFM | -- | -- | -- | -- | 29.3 | 35.6 | 44.4 | 53.13 | |

| SLPM | -- | -- | -- | -- | 830 | 1008 | 1257 | 1505 | ||

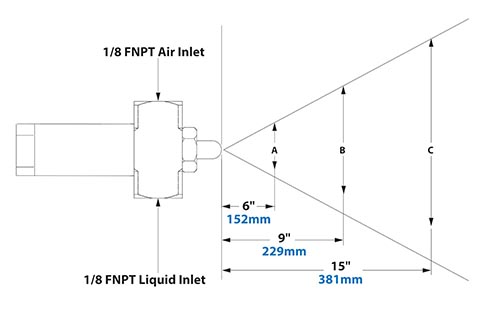

Spray DimensionsNo Drip Internal Mix Flat Fan Pattern Atomizing Nozzle(1/8 FNPT Models) |

||||||||||||

|

||||||||||||

Model |

Air Pressure |

Liquid Pressure |

Width |

Max Depth |

||||||||

PSI |

BAR |

PSI |

BAR |

A |

B |

C |

ft |

m |

||||

in |

cm |

in |

cm |

in |

cm |

|||||||

| AF9010SS | 10 | 0.7 | 10 | 0.7 | 14 | 36 | 18 | 46 | 25 | 64 | 1 | 0.3 |

| 26 | 1.8 | 20 | 1.4 | 15 | 38 | 22 | 56 | 30 | 76 | 2 | 0.6 | |

| 36 | 2.5 | 30 | 2.1 | 14 | 36 | 22 | 56 | 30 | 76 | 2 | 0.6 | |

| 100 | 6.9 | 60 | 4.1 | 22 | 56 | 30 | 76 | 46 | 117 | 3 | 0.9 | |

| AF9020SS | 18 | 1.2 | 10 | 0.7 | 14 | 36 | 17 | 43 | 24 | 61 | 2 | 0.6 |

| 36 | 2.5 | 20 | 1.4 | 18 | 46 | 24 | 61 | 32 | 81 | 3 | 0.9 | |

| 46 | 3.2 | 30 | 2.1 | 23 | 58 | 29 | 74 | 37 | 94 | 3 | 0.9 | |

| 55 | 3.8 | 40 | 2.8 | 30 | 76 | 34 | 86 | 47 | 119 | 4 | 1.2 | |

| AF9030SS | 16 | 1.1 | 10 | 0.7 | 21 | 53 | 26 | 66 | 32 | 81 | 3 | 0.9 |

| 30 | 2.1 | 20 | 1.4 | 24 | 61 | 30 | 76 | 39 | 99 | 4 | 1.2 | |

| 42 | 2.9 | 30 | 2.1 | 29 | 74 | 36 | 91 | 44 | 112 | 4 | 1.2 | |

| 56 | 3.9 | 40 | 2.8 | 32 | 81 | 39 | 99 | 47 | 119 | 4 | 1.2 | |

| AF9040SS | 12 | 0.8 | 10 | 0.7 | 20 | 51 | 24 | 61 | 31 | 79 | 3 | 0.9 |

| 26 | 1.8 | 20 | 1.4 | 25 | 64 | 29 | 74 | 36 | 91 | 4 | 1.2 | |

| 60 | 4.1 | 40 | 2.8 | 26 | 66 | 31 | 79 | 42 | 107 | 6 | 1.8 | |

| 100 | 6.9 | 60 | 4.1 | 32 | 81 | 39 | 99 | 44 | 112 | 7 | 2.1 | |

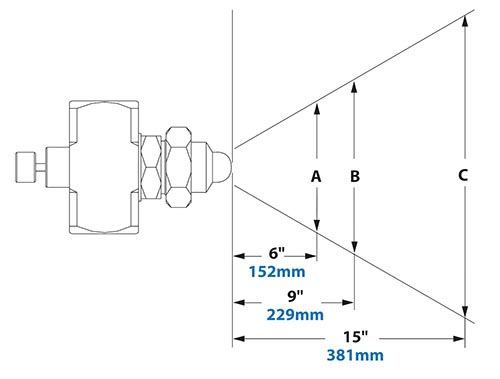

Spray DimensionsNo Drip Internal Mix Flat Fan Pattern Atomizing Nozzle(1/4 FNPT Models) |

||||||||||||

|

||||||||||||

Model |

Air Pressure |

Liquid Pressure |

Width |

Max Depth |

||||||||

PSI |

BAR |

PSI |

BAR |

A |

B |

C |

ft |

m |

||||

in |

cm |

in |

cm |

in |

cm |

|||||||

| AF2010SS | 16 | 1.1 | 10 | 0.7 | 9 | 23 | 12 | 30 | 15 | 38 | 5 | 1.5 |

| 30 | 2.1 | 20 | 1.4 | 11 | 28 | 13 | 33 | 17 | 43 | 6 | 1.8 | |

| 40 | 2.8 | 30 | 2.1 | 12 | 30 | 14 | 36 | 20 | 51 | 6 | 1.8 | |

| 50 | 3.4 | 40 | 2.8 | 14 | 36 | 16 | 41 | 22 | 56 | 7 | 2.1 | |

| 85 | 5.9 | 60 | 4.1 | 14 | 36 | 17 | 43 | 23 | 58 | 7 | 2.1 | |

| AF2020SS | 16 | 1.1 | 10 | 0.7 | 11 | 28 | 14 | 36 | 19 | 48 | 5 | 1.5 |

| 30 | 2.1 | 20 | 1.4 | 14 | 36 | 17 | 43 | 21 | 53 | 6 | 1.8 | |

| 42 | 2.9 | 30 | 2.1 | 14 | 36 | 18 | 46 | 23 | 58 | 6 | 1.8 | |

| 50 | 3.4 | 40 | 2.8 | 16 | 41 | 19 | 48 | 26 | 66 | 7 | 2.1 | |

| 80 | 5.5 | 60 | 4.1 | 16 | 41 | 21 | 53 | 29 | 74 | 8 | 2.4 | |

| AF2030SS | 20 | 1.4 | 10 | 0.7 | 11 | 28 | 14 | 36 | 19 | 48 | 10 | 3.0 |

| 32 | 2.2 | 20 | 1.4 | 15 | 38 | 17 | 43 | 23 | 58 | 11 | 3.4 | |

| 42 | 2.9 | 30 | 2.1 | 16 | 41 | 21 | 53 | 29 | 74 | 12 | 3.7 | |

| 54 | 3.7 | 40 | 2.8 | 19 | 48 | 25 | 64 | 33 | 84 | 14 | 4.3 | |

| 75 | 5.2 | 60 | 4.1 | 20 | 51 | 26 | 66 | 35 | 89 | 15 | 4.6 | |

| AF2040SS | 16 | 1.1 | 10 | 0.7 | 14 | 36 | 18 | 46 | 24 | 61 | 10 | 3.0 |

| 32 | 2.2 | 20 | 1.4 | 15 | 38 | 19 | 48 | 27 | 69 | 12 | 3.7 | |

| 46 | 3.2 | 30 | 2.1 | 17 | 43 | 23 | 58 | 30 | 76 | 13 | 4.0 | |

| 56 | 3.9 | 40 | 2.8 | 20 | 51 | 25 | 64 | 34 | 86 | 15 | 4.6 | |

| 85 | 59 | 60 | 4.1 | 21 | 53 | 27 | 69 | 36 | 91 | 15 | 4.6 | |

| AF2050SS | 14 | 1.0 | 10 | 0.7 | 14 | 36 | 18 | 46 | 23 | 58 | 10 | 3.0 |

| 26 | 1.8 | 20 | 1.4 | 15 | 38 | 19 | 48 | 24 | 61 | 13 | 4.0 | |

| 38 | 2.6 | 30 | 2.1 | 16 | 41 | 20 | 51 | 25 | 64 | 16 | 4.9 | |

| 48 | 3.3 | 40 | 2.8 | 17 | 43 | 20 | 51 | 27 | 69 | 18 | 5.5 | |

| 70 | 4.8 | 60 | 4.1 | 17 | 43 | 21 | 53 | 29 | 74 | 19 | 5.8 | |

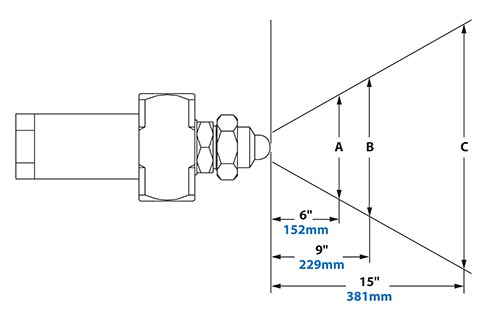

Spray DimensionsNo Drip Internal Mix Flat Fan Pattern Atomizing Nozzle(1/2 FNPT Models) |

||||||||||||

|

||||||||||||

Model |

Air Pressure |

Liquid Pressure |

Width |

Max Depth |

||||||||

PSI |

BAR |

PSI |

BAR |

A |

B |

C |

ft |

m |

||||

in |

cm |

in |

cm |

in |

cm |

|||||||

| AF6010SS | 20 | 1.4 | 10 | 0.7 | 25 | 64 | 34 | 86 | 45 | 114 | 14 | 4.3 |

| 40 | 2.8 | 20 | 1.4 | 28 | 71 | 36 | 91 | 46 | 117 | 18 | 5.5 | |

| 50 | 3.4 | 25 | 1.7 | 29 | 74 | 38 | 97 | 48 | 122 | 22 | 6.7 | |

| 70 | 4.8 | 40 | 2.8 | 32 | 81 | 42 | 107 | 51 | 130 | 27 | 8.2 | |

| AF6020SS | 10 | 0.7 | 5 | 0.3 | 21 | 53 | 27 | 69 | 36 | 91 | 13 | 4.0 |

| 20 | 1.4 | 15 | 1.0 | 34 | 86 | 42 | 107 | 52 | 132 | 15 | 4.6 | |

| 44 | 3.0 | 35 | 2.4 | 39 | 99 | 47 | 119 | 64 | 163 | 19 | 5.8 | |

| 64 | 4.4 | 55 | 3.8 | 40 | 102 | 50 | 127 | 68 | 173 | 20 | 6.1 | |

Atomizing Nozzle Standards and Certifications

EXAIR Atomizing Nozzles comply with the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC). All sound level measurements are taken at 3 feet away.

Look for this symbol to designate conflict mineral free products throughout our website. EXAIR supports Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act and we are committed to compliance with the conflict minerals rule in order to curb the illicit trade of tin, tantalum, tungsten and gold in the DRC region. EXAIR is using the CMRT 3.02 template to document our supply chain and commitment to conflict free products.

Awards - No Drip Internal Mix Atomizing Nozzle

EXAIR's No Drip Internal Mix Atomizing Nozzles were a finalist in the 2017 Plant Engineering Product of the Year Awards. The No Drip Internal Mix Atomizing Nozzle family placed in the Fluid Handling category.

EXAIR's No Drip Internal Mix Atomizing Nozzles were a finalist in the 2015 Plant Engineering Product of the Year Awards. The No Drip Internal Mix Atomizing Nozzle family placed in the Fluid Handling category.

Droplet Size

One of the primary reasons atomizing spray nozzles are used is because of their fine droplet size. Benefits of fine droplet size include even coating and liquid conservation. For reference, a large raindrop is around 6,000 microns (0.236") in diameter. Standard liquid nozzles produce droplet sizes ranging from 4,000 microns (0.157") down to 300 microns (0.012") in diameter. EXAIR's Atomizing Nozzles produce minuscule droplet sizes in the range of 100 microns (0.004") to 20 microns (0.0008")!

Droplet Size | |||

| Model | Liquid Pressure | Air Pressure | Droplet Size (μm*) |

| AN1020SS | 20PSI | 40 PSI | 71 |

| 40PSI | 65 PSI | 83 | |

| ER1020SS | 5 PSI | 40 PSI | 39 |

| 20 PSI | 40 PSI | 57 | |

| SR1020SS | 4" Siphon Height | 20 PSI | 25 |

| 4" Siphon Height | 40 PSI | 22 | |

*Volume Median Diameter Dv(50.0) of liquid droplets. 1μ = 1 micron = 0.00004". All tests performed with water. | |||

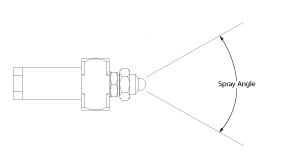

Spray Angle

The Spray Angle is the trigonometric angle created by the width of the spray pattern and the distance at which it is measured. This angle can vary greatly within a given family of atomizing nozzles depending on flow rates and pressures, but will generally fall into the ranges below:

Spray Angle |

||

| Model Family | Minimum Angle | Maximum Angle |

| Internal Mix Narrow Angle Round Pattern- AN1010SS, AN2010SS, etc. | 20° | 45° |

| Internal Mix Wide Angle Round Pattern- AW1010SS, AW2010SS, etc. | 50° | 90° |

| Internal Mix Flat Fan Pattern- AF1010SS, AF2010SS, etc. | 50° | 120° |

| External Mix Round Pattern - ER1010SS, ER2010SS, etc. | 25° | 60° |

| External Mix Narrow Angle Flat Fan Pattern - EF1010SS, EF2010SS, etc. | 35° | 70° |

| External Mix Wide Angle Flat Fan Pattern - EB1010SS, EB2010SS, etc. | 50° | 105° |

| Siphon Fed Round Pattern SR1010SS, SR2010SS, etc. | 20° | 50° |

| Siphon Fed Flat Fan Pattern SF1010SS, SF2010SS, etc. | 50° | 100° |

-

Model 901547-F200 Air Cap for AF6020SS

Model 901547-F200 Air Cap for AF6020SS -

Model AF6020SS 231 GPH No Drip Internal Mix Flat Fan Atomizing Nozzle

Model AF6020SS 231 GPH No Drip Internal Mix Flat Fan Atomizing Nozzle