HollowStream™ Cone Liquid Atomizing Nozzle, 1/4 NPT

Applications

- Cooling, coating

- Quenching

- Dust suppression

- Washing, rinsing

- Foam breaking

- Slurry spraying

- Sanitizing, degreasing

- Lubricating

Advantages

- Lower liquid flow rates compared to full cone counterparts

- Increase surface area coverage

- Increase liquid volume on your target

- All stainless steel construction

- Compact footprint, versatile

Liquid Atomizing Spray Nozzle Materials

Type 303 Stainless Steel - All of EXAIR's Liquid Atomizing Nozzles are constructed with Type 303 stainless steel, which can resist high temperatures and corrosive environments. They are designed for environments with a maximum operating temperature of 800°F (426°C).

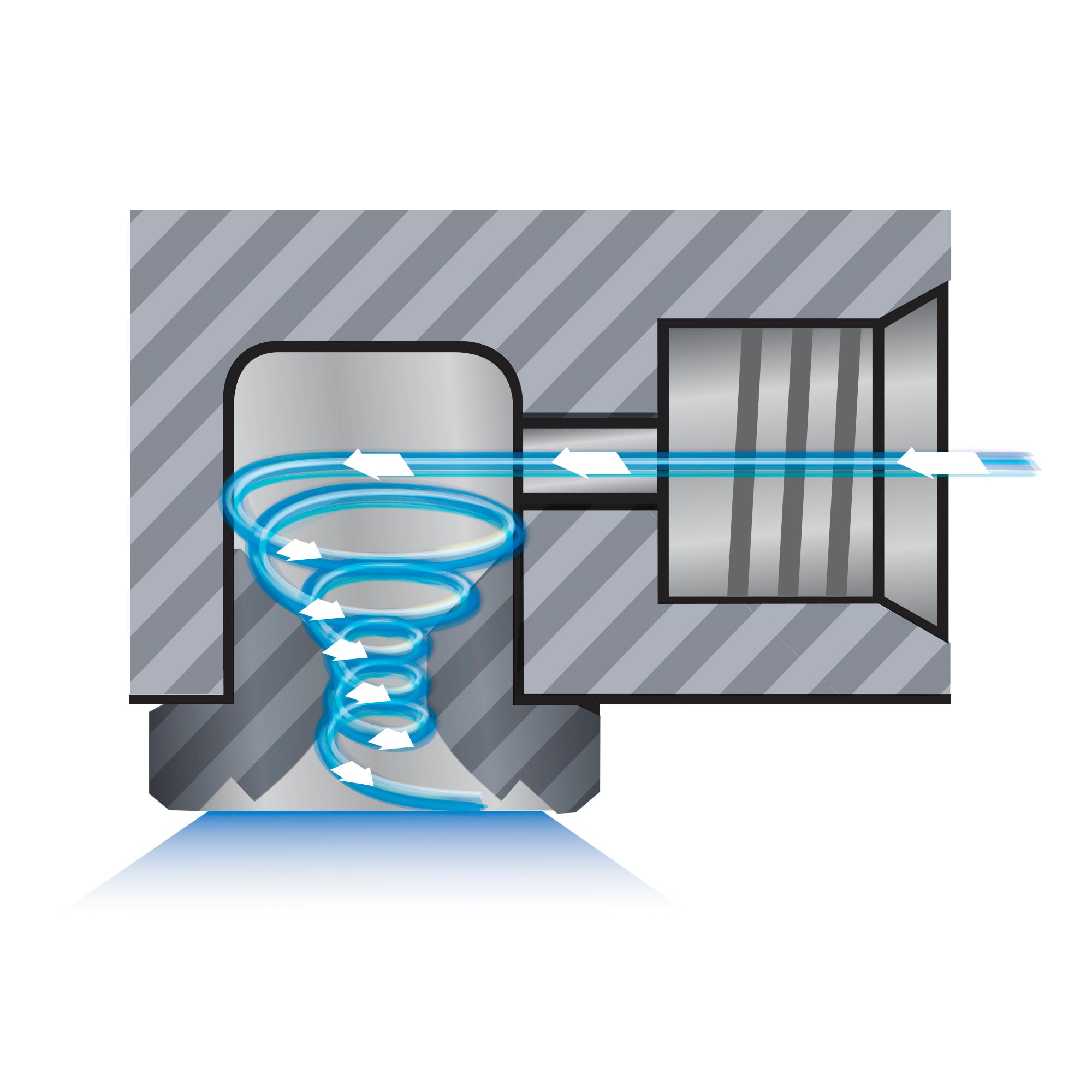

How FullStream and HollowStream Cone Nozzles Work | |

| |

With these nozzles, the atomizing fluid is supplied into the body of the nozzle creating a swirling action within the vortex chamber. Depending on the geometry of the liquid cap these nozzles will produce a full cone or hollow cone liquid spray pattern as it exits the orifice at a controlled spray angle. | |

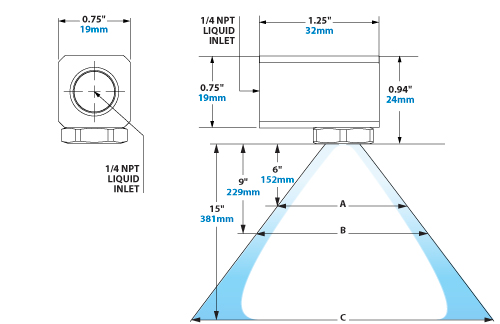

Spray DimensionsHollowStream Cone Liquid Atomizing Nozzle(1/4 NPT Models) |

||||

|

||||

Model |

Pressure |

Width (inches) |

||

| HL1001SS | A | B | C | |

| 7 PSI | 4.8 | 6.1 | 7.8 | |

| 20 PSI | 7.3 | 9.2 | 11.7 | |

| 60 PSI | 12.1 | 15.3 | 19.5 | |

| HL1002SS | A | B | C | |

| 7 PSI | 6.1 | 8.6 | 11.2 | |

| 20 PSI | 9.2 | 12.8 | 16.8 | |

| 60 PSI | 15.3 | 21.4 | 28.0 | |

| HL1003SS | A | B | C | |

| 7 PSI | 6.8 | 10.4 | 13.3 | |

| 20 PSI | 10.2 | 15.6 | 20.0 | |

| 60 PSI | 17.0 | 26.1 | 33.3 | |

| HL1005SS | A | B | C | |

| 7 PSI | 8.4 | 9.7 | 14.3 | |

| 20 PSI | 12.6 | 14.6 | 21.5 | |

| 60 PSI | 21.0 | 24.3 | 35.8 | |

| HL1008SS | A | B | C | |

| 7 PSI | 7.1 | 7.8 | 10.1 | |

| 20 PSI | 10.6 | 11.7 | 15.1 | |

| 60 PSI | 17.7 | 19.5 | 25.2 | |

| HL1011SS | A | B | C | |

| 7 PSI | 9.5 | 12.0 | 14.8 | |

| 20 PSI | 14.3 | 18.0 | 22.2 | |

| 60 PSI | 23.9 | 30.0 | 37.0 | |

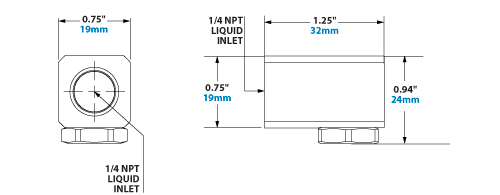

Dimensions & PerformanceHollowStream Cone Liquid Atomizing Nozzle(1/4 NPT Models) |

|||||

|

|||||

Model |

HL1001SS |

HL1002SS |

HL1003SS |

HL1005SS |

|

Inlet Connection |

1/4 NPT | 1/4 NPT | 1/4 NPT | 1/4 NPT | |

Capacity |

1 | 2 | 3 | 5 | |

Max Free Passage |

0.052" | 0.086" | 0.109" | 0.120" | |

Flow Rate

|

HL1001SS |

HL1002SS |

HL1003SS |

HL1005SS |

|

| 3 PSI | GPM | 0.06 | 0.14 | 0.20 | 0.27 |

| LPM | 0.23 | 0.53 | 0.76 | 1.02 | |

| 5 PSI | GPM | 0.07 | 0.17 | 0.24 | 0.35 |

| LPM | 0.26 | 0.64 | 0.91 | 1.32 | |

| 7 PSI | GPM | 0.09 | 0.19 | 0.28 | 0.39 |

| LPM | 0.34 | 0.72 | 1.06 | 1.47 | |

| 10 PSI | GPM | 0.10 | 0.20 | 0.32 | 0.49 |

| LPM | 0.38 | 0.76 | 1.21 | 1.85 | |

| 20 PSI | GPM | 0.13 | 0.27 | 0.45 | 0.65 |

| LPM | 0.49 | 1.02 | 1.70 | 2.46 | |

| 40 PSI | GPM | 0.18 | 0.38 | 0.63 | 0.91 |

| LPM | 0.68 | 1.44 | 2.38 | 3.44 | |

| 60 PSI | GPM | 0.21 | 0.46 | 0.77 | 1.12 |

| LPM | 0.79 | 1.74 | 2.91 | 4.23 | |

Model |

HL1008SS |

HL1011SS |

|

Inlet Connection |

1/4 NPT | 1/4 NPT | |

Capacity |

8 | 11 | |

Max Free Passage |

0.166" | 0.180" | |

Flow Rate

|

HL1008SS |

HL1011SS |

|

| 3 PSI | GPM | 0.46 | 0.65 |

| LPM | 1.74 | 2.46 | |

| 5 PSI | GPM | 0.59 | 0.81 |

| LPM | 2.23 | 3.06 | |

| 7 PSI | GPM | 0.73 | 0.93 |

| LPM | 2.76 | 3.52 | |

| 10 PSI | GPM | 0.80 | 1.10 |

| LPM | 3.02 | 4.16 | |

| 20 PSI | GPM | 1.16 | 1.47 |

| LPM | 4.38 | 5.56 | |

| 40 PSI | GPM | 1.60 | 2.03 |

| LPM | 6.05 | 7.67 | |

| 60 PSI | GPM | 2.04 | 2.50 |

| LPM | 7.71 | 9.45 | |

Liquid Atomizing Spray Nozzle Standards and Certifications

EXAIR Liquid Atomizing Spray Nozzles comply with the EU General Product Safety Directive (2001/95/EC) and meet the noise limitation requirements of the EU Machinery Directive (2006/42/EC). All sound level measurements are taken at 3 feet away.

Look for this symbol to designate conflict mineral free products throughout our website. EXAIR supports Section 1502 of the Dodd-Frank Wall Street Reform and Consumer Protection Act and we are committed to compliance with the conflict minerals rule in order to curb the illicit trade of tin, tantalum, tungsten and gold in the DRC region. EXAIR is using the CMRT 3.02 template to document our supply chain and commitment to conflict free products.

-

HollowStream Cone Liquid Atomizing Nozzle, 1/4 NPT

HollowStream Cone Liquid Atomizing Nozzle, 1/4 NPT -

Model HL1001SS 1/4 NPT HollowStream Cone Nozzle, 0.1 GPM

Model HL1001SS 1/4 NPT HollowStream Cone Nozzle, 0.1 GPM -

1/8 NPT HollowStream Liquid Atomizing Nozzles

1/8 NPT HollowStream Liquid Atomizing Nozzles